NASCAR-Inspired Mopar® Muscle!

– NASCAR-inspired Dodge Charger tested in Lockheed-Georgia wind tunnel

– HEMI® 4-speed with A33 Track Pak

– “Survivor” with original engine and driveline

Factory rivalries were intense during the late 1960s in NASCAR (National Association for Stock Car Auto Racing) competition; the battle was on to see who could build a winner on the high-banked superspeedways. Ford and Mercury were heavily involved (factory supported) in stock car racing, and Chrysler Corporation had two separate divisions involved in the racing, Dodge and Plymouth, and even though both brands used similar “B-body” sized cars to race with, there were differences between them. General Motors (Chevrolet) had some involvement; however, it was done through the “back door” of the factory and with nowhere near the intensity of the Ford/Mercury and Dodge/Plymouth programs.

When the second-generation Dodge Charger was released, Dodge’s General Manager Bob McCurry stated the new curvy creation had “jet-age aerodynamic styling.” The new Charger featured fresh, new Coke-bottle-shaped sides, where the body is narrower in the door area as compared to the bulged fender contours (in the overhead view), plus it now featured a built-in rear spoiler lip and racing-style pop-up fuel filler cap as standard equipment. The new 1968 model certainly was a visual improvement over what it replaced and in no way showed any resemblance to the original Charger.

The buying public liked the new Charger shape so much that the sales went up in excess of 450 percent over the dismal sales of 1967 models. The shapely new Dodge was a big hit! The only fly in the ointment was that the body design was terrible on the racetracks of NASCAR! Up front, the ’68 Dodge Charger incorporated a deeply sunken grille design and it was discovered that at speeds well over 100 miles per hour, the car, in race form (where the front end was lowered and fitted with an air dam) experienced steering problems after the car came charging down the straightaway in preparing for the left-hand turn.

What was happening was the oncoming air was rushing into the deep grille cavity with no place to go, the recessed design of the grille was acting as a huge air scoop, causing aerodynamic havoc to the point where when the race driver cranked the wheel to the left, or to the right for that matter, the car kept going straight. The only way to negotiate the corner was to get on the brakes and slow the car down to a point where the problem went away.

FLUSH GRILLE

The decision was made by the Dodge factory to “correct” these aerodynamic flaws of the Charger body and soon tests were conducted in the wind tunnel (using both 3/8-scale models as well as full-sized cars) to find out the best way to solve the ailments. The front grille drama was solved by the fitting of a 1968 Coronet grille in the most forward area of the grille cavity, virtually eliminating and recessed area, as it was now flush fitted. The hide-a-way headlight feature of the standard ’68 Charger was now eliminated, as the lower-priced Coronet models didn’t include them, but using exposed headlamps was of no concern to the aerodynamic team.

REVISED BACKLIGHT GLASS

Another race-related issue of the new ’68 Charger was the “flying buttress” design of the backlight (rear window). What is a flying buttress? It’s a roofline that features sail-fin panels on each side of the backlight which extends rearward, to the point of appearing like a semi-fastback roof from the side views. This layout is attractive and rather stylish, however, it creates air turbulence problems because of the “tunnel effect” that results with the backlight glass being set at a steep, more vertical angle, like on a regular hardtop model. The Dodge racing division had some real problems on their hands.

The aerodynamic specialists from Chrysler also found that welding a metal “plug” to the backlight area, covering the recessed area and using a flat-shaped rear glass window was the simplest way to deal with the turbulence problems. With these modifications, the rear lift was solved to the best of their ability. The air stream now traveled in a more advantageous manner. Slippery!

SURVIVOR WITH ZERO RUST!

The featured car pictured here is an unrestored, pristine example is a factory HEMI car with 4-speed transmission, 70,000 actual miles on the clock. The story of the car, rust-free, is that the original owner was in the military and after he purchased the unique Charger 500 he was lucky in the fact that he was soon transferred out of the Northern Minnesota region and to the Luke Air Force Base in the state of Arizona. Luck came in two parts on this move: one, he didn’t have to go to Viet Nam, two; his Charger 500 was now in an extremely dry part of the country and not subject to rust as it surely would have been if left in Minnesota!

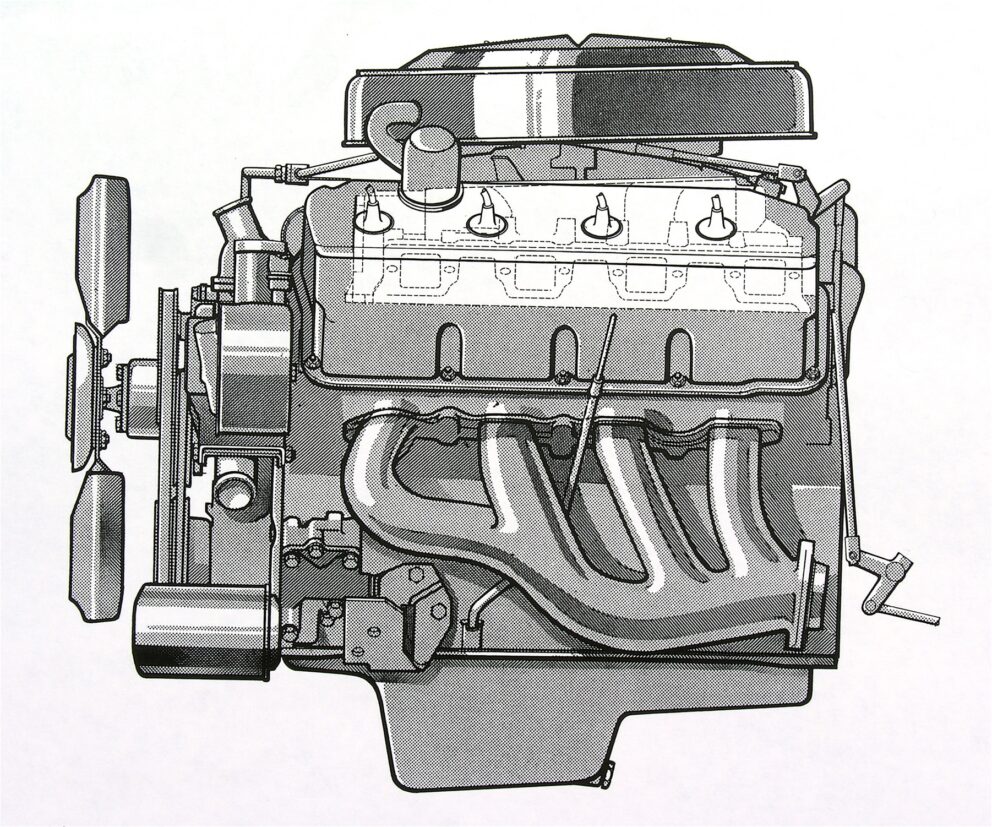

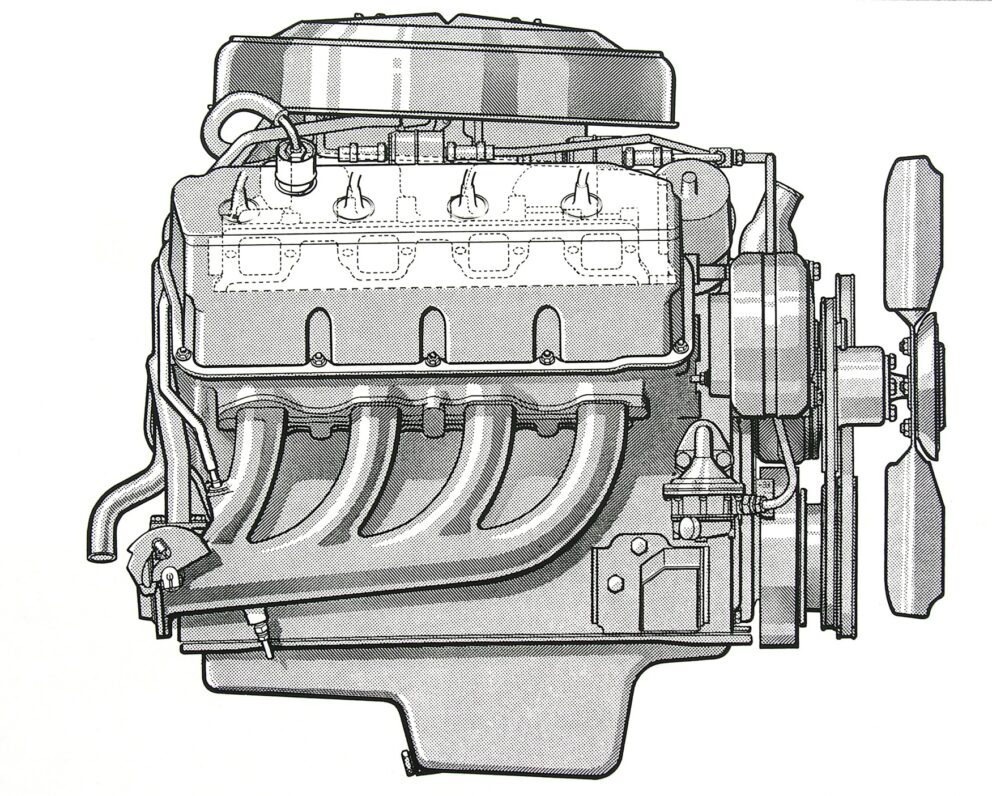

KING-KONG 426 HEMI ENGINE

When you open the hood of a Street HEMI engine-powered car, all you see is engine! 425-hp and tandem-mounted four-barrel carburetors, black wrinkle-finished valve covers, all well worth the $648.20 extra cost. “E74” was the code on the dealer order sheet. The twin Carter four barrels in all their glory as well as specific details of how the fuel lines are routed. This HEMI engine has never been torn down so everything you’re viewing here (save for the hoses and plug wires) is truly factory original.

PRISTINE INTERIOR

Today, the interior looks picture-perfect to the day it rolled off the Hamtramck Assembly line, right down to the stock Hurst shifter and plastic wood grain shifter ball. The dash-mounted tachometer with clock is known as the N85 option.

CHARGER 500 FEATURES

The Coronet grille was fitted with a “Charger 500” emblem for quick ID. Tests that Chrysler did in the Lockheed-Georgia wind tunnel showed a slight reduction in wind drag by shaping the A-Pillar posts as smooth as possible, so these covers were designed and installed on all Charger 500s. The rear bumblebee strip had the “500” marking, in case someone missed the body mods! Because of the revived back glass, a unique deck lid was required. Records indicate a total of 392 Charger 500s were built for the 1969 sales year.

YEAH, ITS GOT A HEMI!

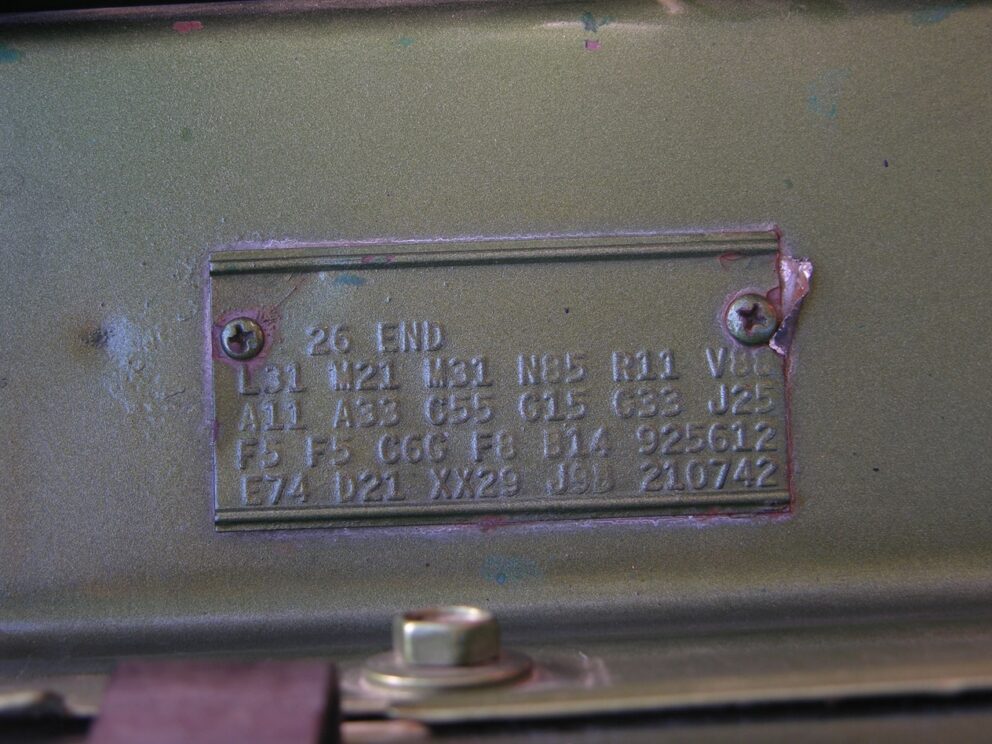

1969 Chargers with HEMI engines have these door emblems, and as cool as they look, they did have a way of discouraging other motorists to take a run at a street race! “E74” on the fender tag confirms that it was factory installed.

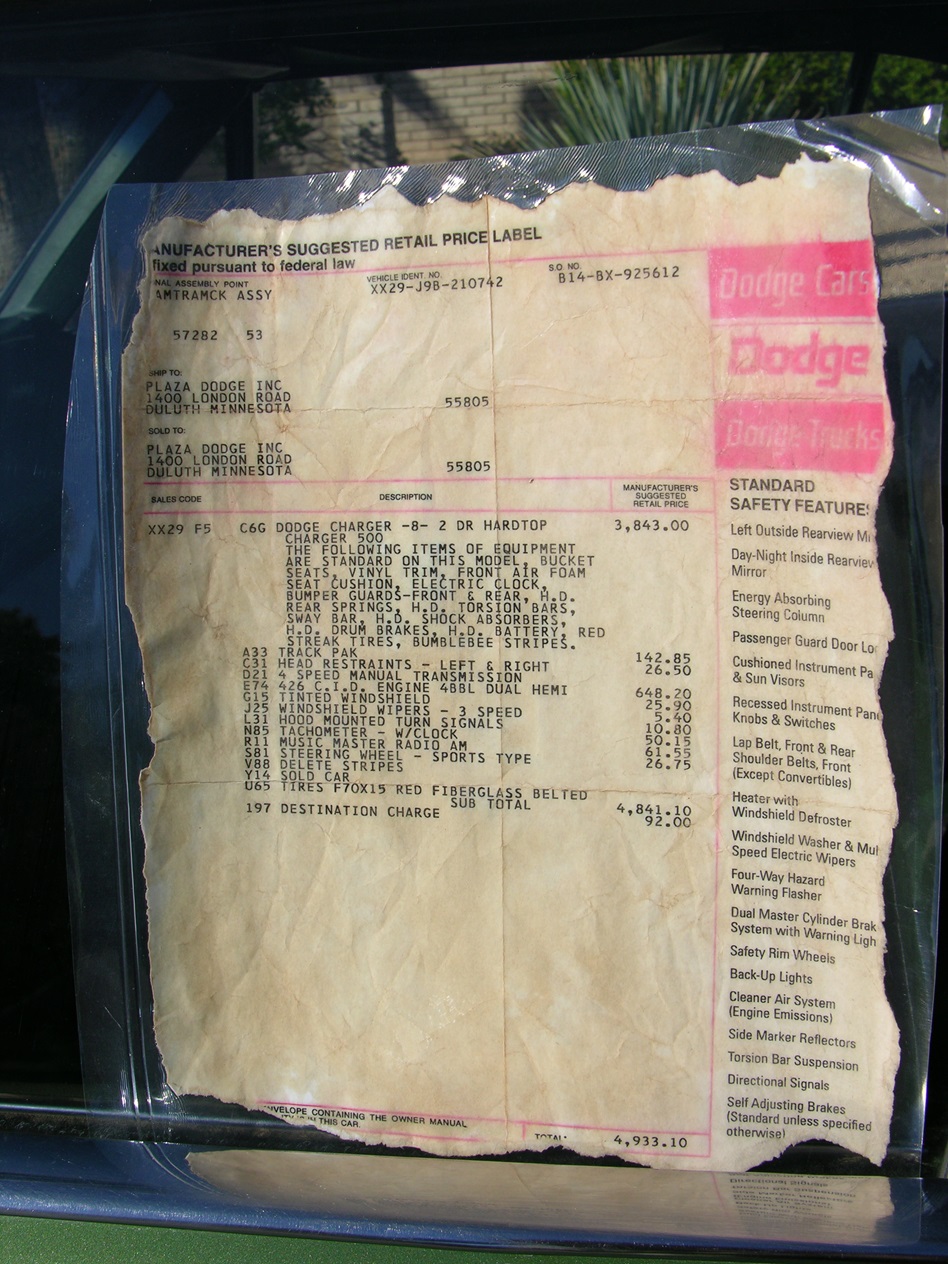

$4,933.10 OUT THE DOOR

The car came out of a dealership in Duluth, MN, and looking closely it shows that this particular Charger 500 had “V88” listed (delete stripes) and “U65” F70x15 redline tires, dog dish hub caps.

Under the hood, it’s all as built from the factory, and small details like the antifreeze sticker is exactly as applied from when the car was originally built … it’s like a rolling time capsule!

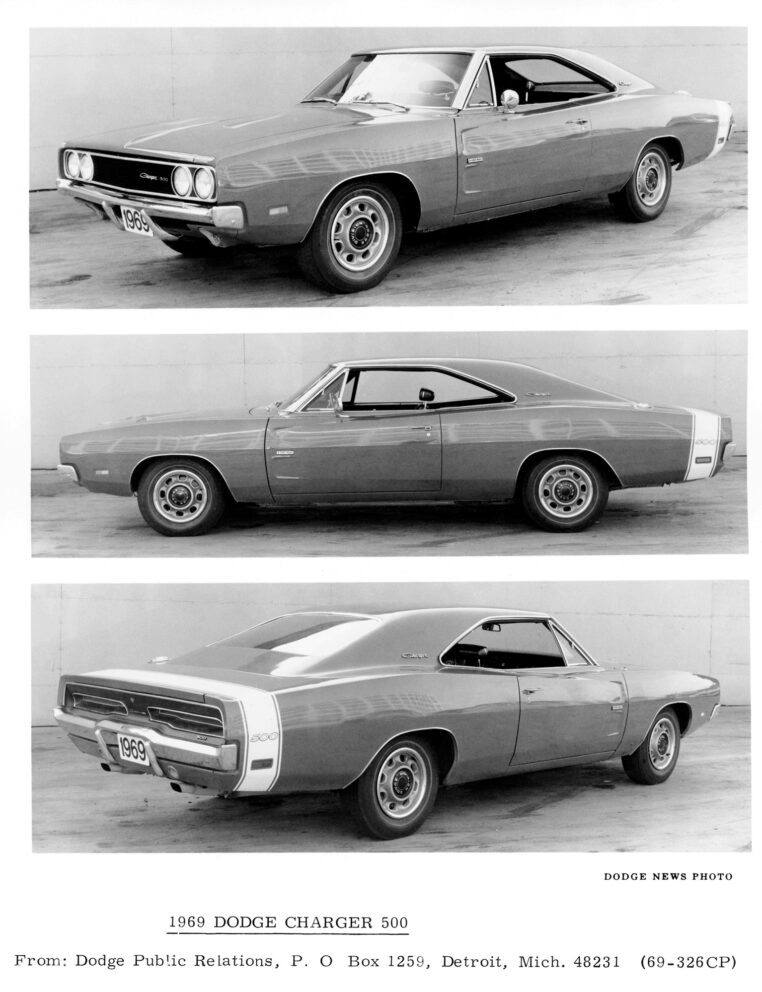

ORIGINAL PRESS PICS

In June 1968, when the factory first showed the press the new 1969 “500” version of the Charger, it actually was a modified 1968 car with the aerodynamic enhancements added. The sample car and press photos sent out to the media featured round side marker lights (as used only on the ’68 models), that were incorrect for the 1969 model year. Rectangular marker lights were 1969 equipment. On this press car, the rear bumblebee stripe had to be moved forward a few inches in order for the round sidelights to not interfere with the new “500” insignia.

The official press photos were in B&W with three images, 1969 markings, with another taken at Riverside International Raceway.

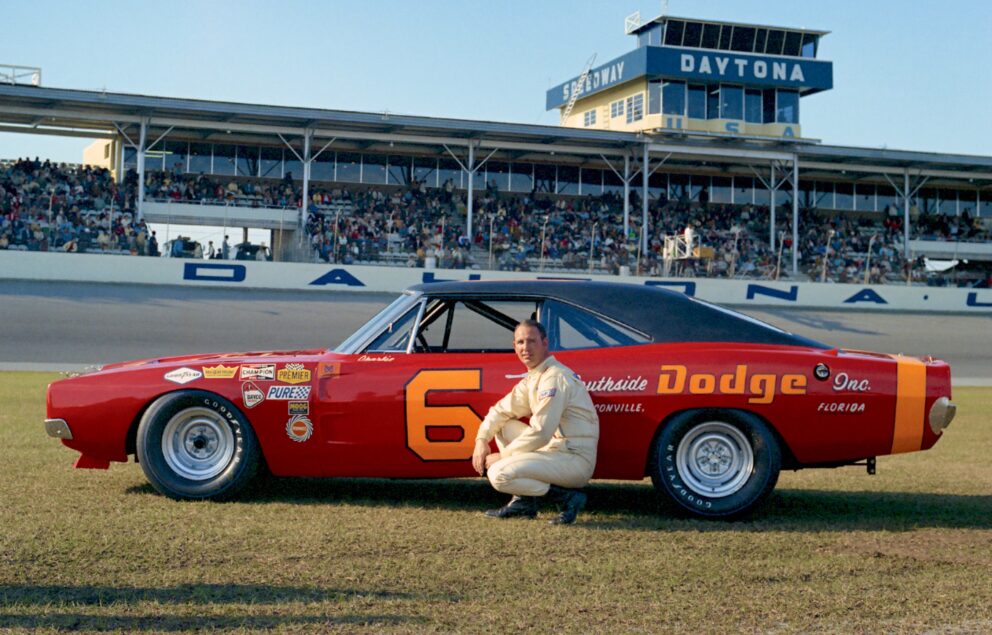

RACECARS!

The 1968 racing season didn’t go too well for the Dodge racers, the concave grille didn’t work well in the corners and the aero needed help to compete with the Ford/Mecury racers.

The “500” version of the Charger did see improved aerodynamics; however, it was a temporary help as the winged “Daytona” was already in the works.

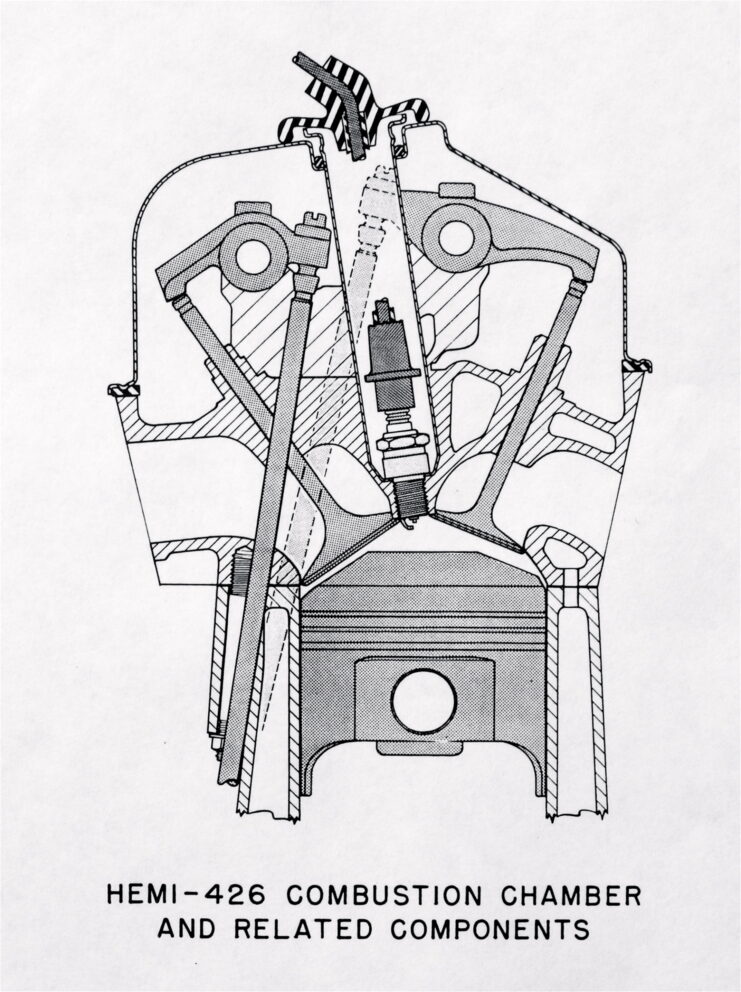

LEGENDARY HEMI ENGINE

Even all these years later, just to view the drawings of the 426 HEMI engine is to see a true work of automotive art!

Author: James Maxwell

0 Comments