DSR Performance, based in Brownsburg, Indiana – the heartland of American drag racing – has built its reputation as both a championship-winning racing team and an innovative manufacturer. Their deep roots in professional motorsports, including their long-standing partnership with Direct Connection and current collaboration with Tony Stewart Racing’s NHRA program, provided the perfect foundation for developing what has become one of the most impressive crate engines available today!

The journey began in 2015 with the DragPak program, where DSR focused intensively on the Gen III HEMI® engine platform. Initially driven by drag racing legend Leah Pruett, the program served as a proving ground for the technologies that would eventually make their way into the Direct Connection offering. By 2021, the team recognized an opportunity to bring their racing expertise to the enthusiast market, creating something that transcended the traditional boundaries between track performance and street usability.

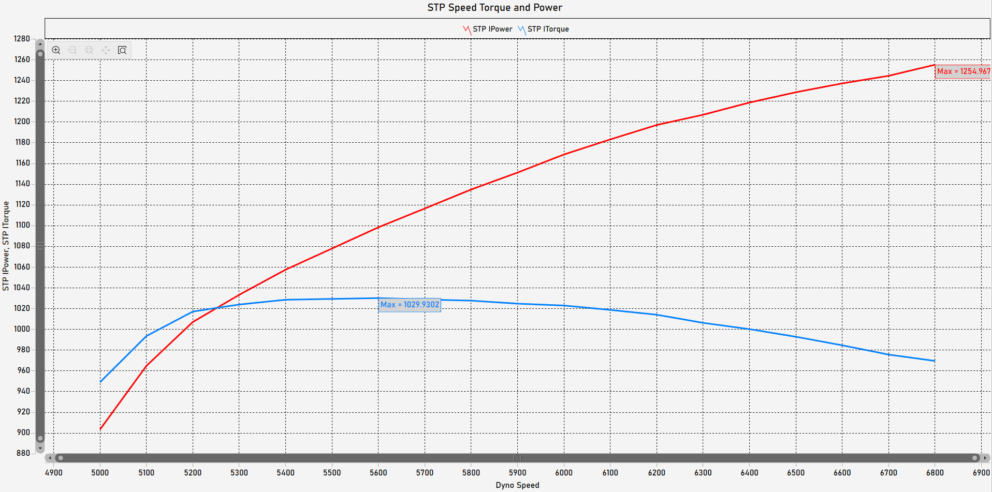

Several aspects of this engine make it truly remarkable, but perhaps the most noteworthy aspect of the Direct Connection 1200 isn’t power alone, it’s how that power is achieved. President of DSR Performance, Chad Osier, explains that the key lies in the engine’s efficiency rather than brute force. “The biggest attributes tied to the engine’s horsepower and torque figures are the boost level and the bottom end,” Osier notes. “We have optimized and engineered this engine to run low boost while still being capable of hitting remarkable power figures on 93 octane pump-gas.”

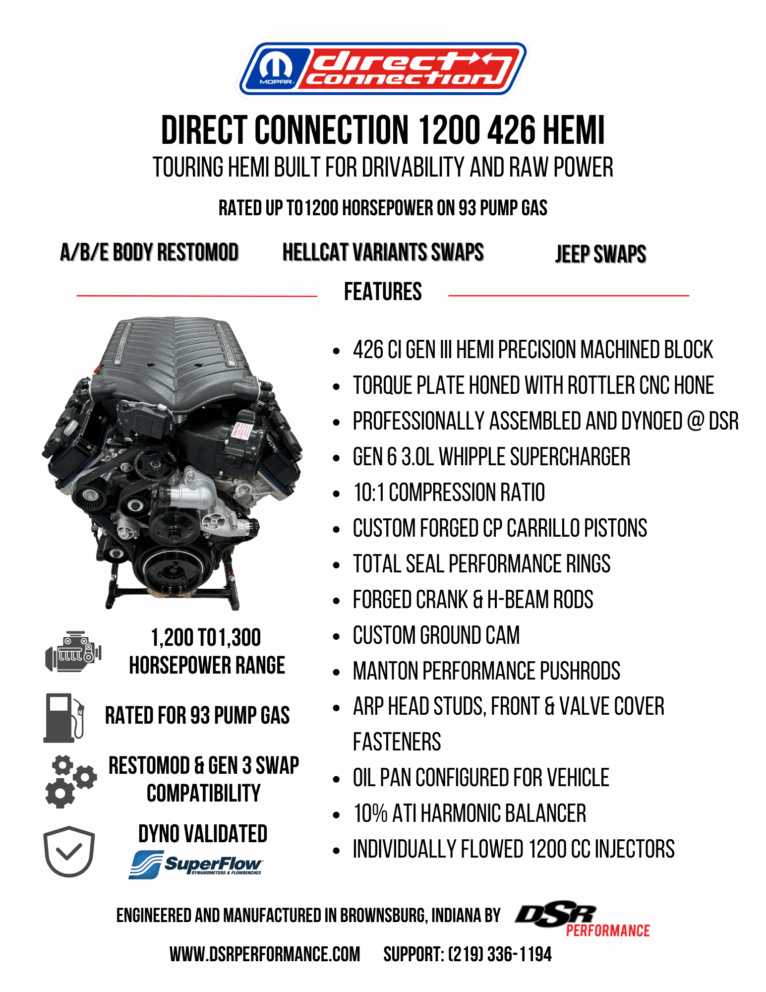

This engineering philosophy centers around what Chad calls a “touring motor” approach. Unlike many high-output engines that sacrifice reliability and daily drivability for peak numbers, the DC-1200 maintains a delicate balance. The engine utilizes factory Dodge cylinder heads – a testament to the original design’s quality – while improving the rotating assembly, pistons, cam design and supercharger optimization.

The technical specifications tell the story of meticulous engineering: a 426-cubic-inch BGE Gen III HEMI cast iron block forms the foundation, topped with a 6th generation 3.0L Whipple supercharger. Inside, a forged Callies crank and H-beam connecting rods work with custom forged CP Carrillo pistons and Total Seal performance rings. The valvetrain features Hellcat aluminum heads with Manton Performance push rods and rocker shaft stabilizers, all secured with ARP fasteners.

One of the most practical aspects of the DC-1200 is its fuel flexibility. While the engine produces its peak 1,200-1,300 horsepower on 93 octane fuel, DSR engineered it to adapt to different fuel availability across the country. “Many people don’t realize we’re dealing with different fuel availability,” Osier explains. “West coast, in the desert and other areas can only get 91 octane the majority of the time.” The engine’s tuning capabilities allow it to be optimized for 91 octane fuel, making it accessible to enthusiasts regardless of their geographic location.

0 Comments