THE HURST AND CHRYSLER CONNECTION PART I

– George Hurst and his early partner Bill Campbell pioneered high-quality shifters

– In 1965, a wild exhibition car was created by Hurst, a mid-engine HEMI® engine-powered Barracuda

– Hurst built the infamous 1968 HEMI Super Stock A-body drag cars

Hurst was a pioneer in designing and selling precision-designed, superior-built shifters for conversion of 3-speed column-mount shifters to floor shift conversions. In addition, Hurst designed and built replacement floor shifters for factory applications of 4-speed manual cars starting in the early 1960s. It was all about quicker shifts for street performance and drag racers.

At that time, the Dodge and Plymouth drag racers mostly relied on the rugged TorqueFlite® 3-speed automatic for the most consistent times, and the racers used the stock dash-mounted transmission gear selector buttons. As a result, that was not a big part of the business that Hurst was having at that moment in time. That soon changed when Chrysler debuted the A-833 4-speed manual transmission in 1964, and in ’65 when their automatic cars switched to the traditional column shift selector. Hurst sales for Mopar® vehicles quickly rose in huge numbers; plus, around this timeframe, the company product line was enlarged with a line of aftermarket 5-spoke wheels.

George Hurst had seen the growth of the “mag wheel” market and decided to manufacture a design of his own, featuring a forged aluminum center section (heat treated) mated to a steel rim, with a removable chrome outside ring. Strong and beautiful, albeit expensive and heavy.

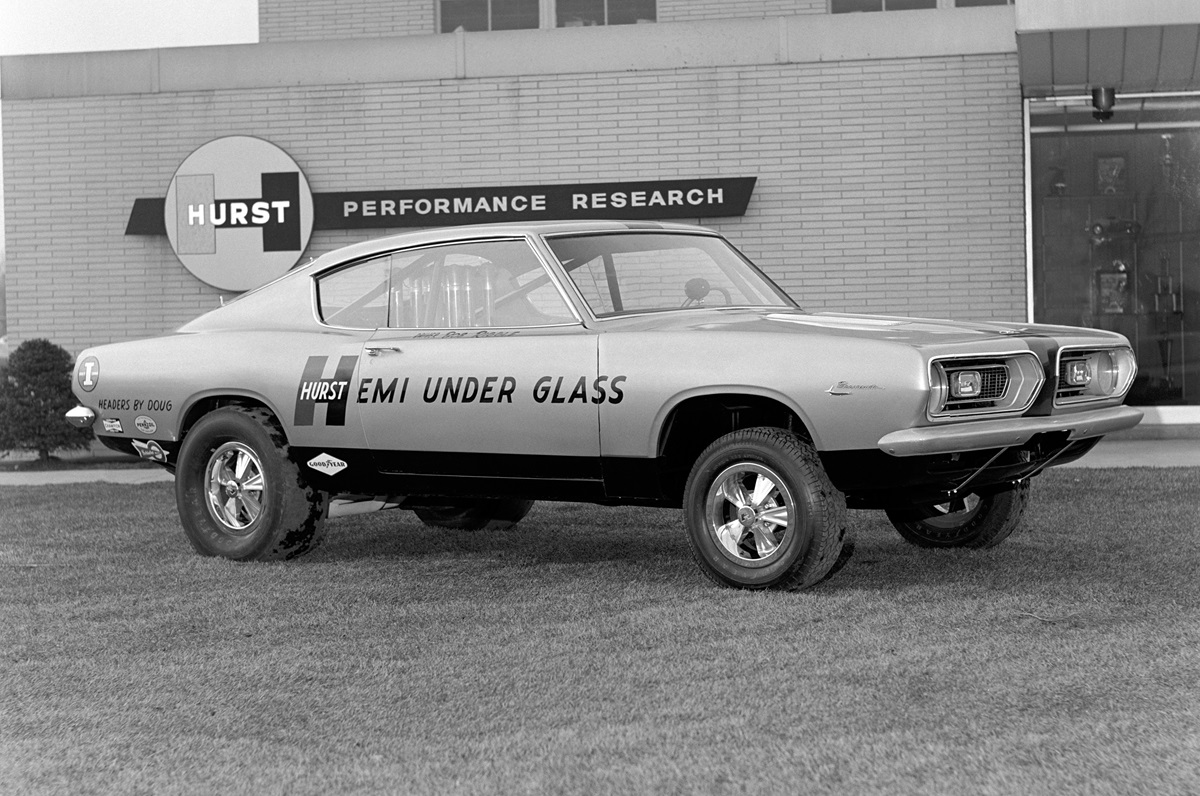

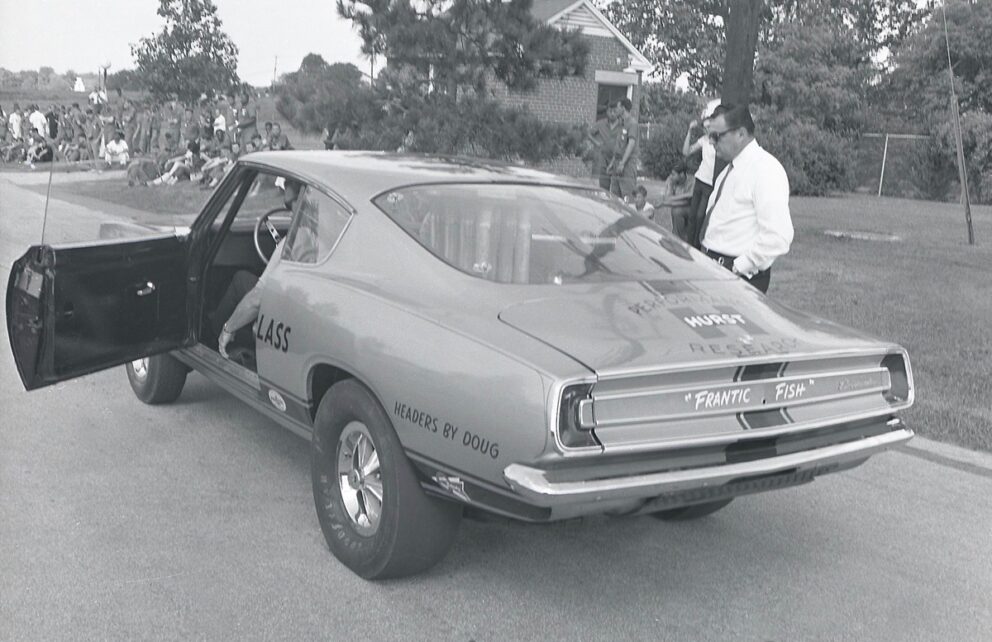

HEMI UNDER GLASS BARRACUDA

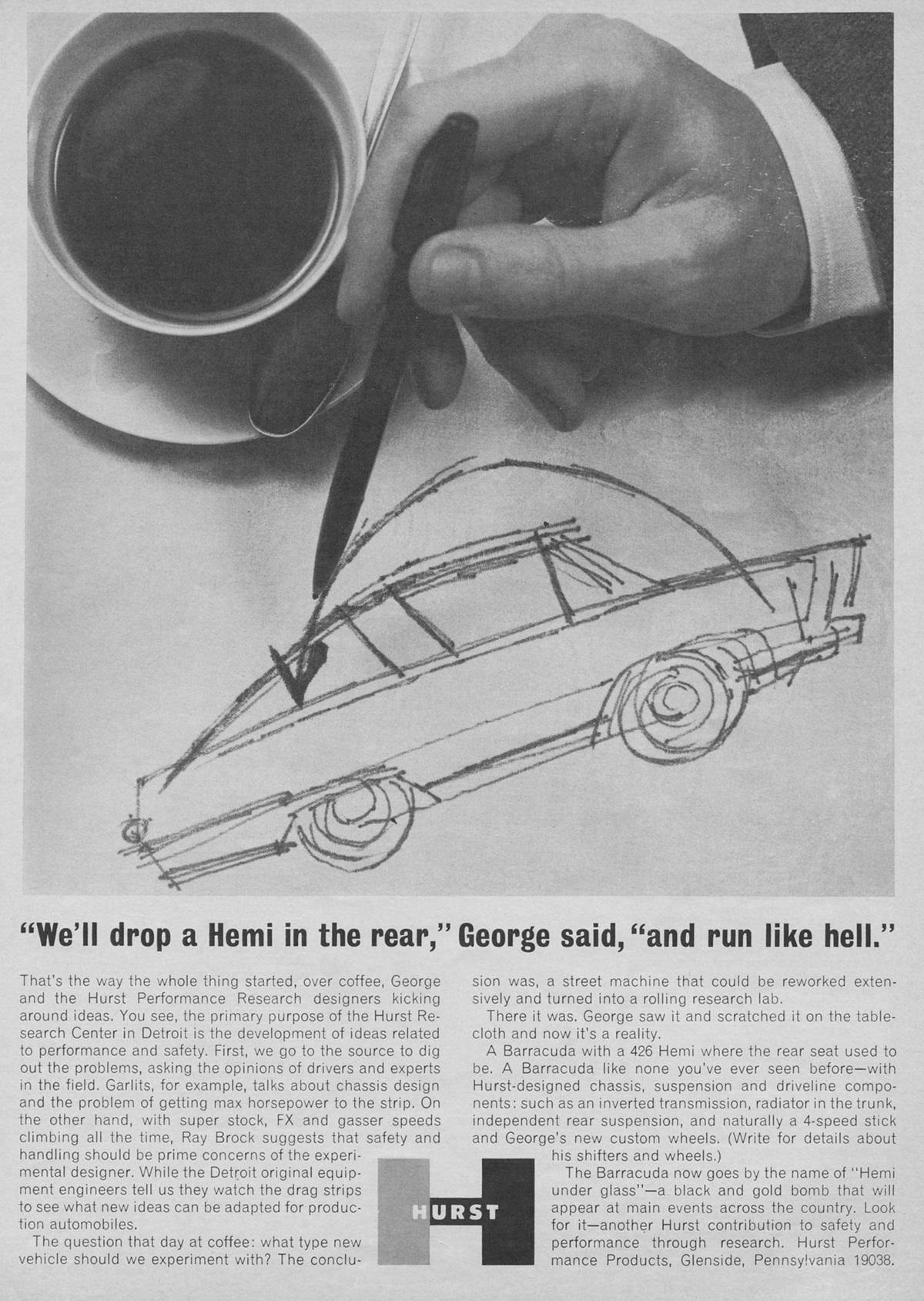

Legend has it, one day over a cup of coffee at a restaurant, George Hurst and Hot Rod Magazine writer Ray Brock were talking about the new Plymouth Barracuda and soon the topic came up to modify one for drag strip duty. Hurst Performance Products needed a “rolling research lab” and the new Plymouth fit the bill. “We’ll drop a HEMI in the rear,” George said, “and run like hell.”

The Barracuda had a large rear window in its fastback design and the idea of installing a 426 HEMI engine under the huge wrap-a-round glass – where the rear seat used to be – brought on the catchy name of “Hemi Under Glass.”

The standard 273-cid V8 under the hood was to be removed and in the rear, the big HEMI engine was the new source of power. A Hurst-designed chassis, revised suspension and heavy-duty driveline components would be constructed, and naturally, a Hurst shifter added! Hurst wasn’t interested in taking trophies away from its customers and this hybrid rear-engined car would not be used to race in any certain eliminator or class.

George got this vision of the Plymouth, scratched out a sketch of it on the tablecloth and it wasn’t long before the unique Black and Gold machine was a reality. Hurst used this story as a full-page advertisement that ran in Hot Rod Magazine and the car became famous in short time, but not for being an all-out drag car but as an exhibition vehicle that greatly entertained the fans at major racing events.

Construction began on a brand-new, stock Barracuda at the Madison Heights, Michigan, Hurst Engineering lab, with the project led by Jack “Doc” Watson and Dave Landrith. First thing done was to yank out the production engine and transmission, along with the radiator. Arrangements were made for the installation of the HEMI engine, and that was to be fitted approximately where the rear seat was. The rear window was removed (and hinged for easy engine access) and soon the real work began.

The Hurst staff installed a square-tube subframe (which was designed to handle the stresses of the big HEMI engine) and it was organized so that the engine was cradled in a fashion where the stock engine mounts could be used. The engine area and cockpit was separated by means of an aluminum firewall, and air for the intake (which was a set of Hilborn injector stacks) was supplied via ducting from the cowl area. Lightweight A/FX-type bucket seats were added, as was a protective roll bar.

A Schiefer clutch assembly was fitted along with a Chrysler New Process 4-speed manual transmission. However, the gearbox itself was inverted for the application and a transfer case was scratch built incorporating two straight-cut gears and twin idlers.

An 8 ¾-inch Chrysler rear differential was used and was flipped upside-down, then modified to work with an I.R.S. system (using Corvette components) and single transverse spring arrangement, a la Corvette as well. An adjustable “roller plate” was created and it allowed for changing the spring rate to best suit the track conditions.

Once the mammoth 426-cid engine was put into place, a set of headers were welded up by Doug Thorley and a 10-quart oil pan (with 360-degree pickup) replaced the stock setup. When the subject of a cooling system came up, the answers came in the way of a Harrison (Corvette) cross-flow aluminum radiator and twin electric fans being mounted to the area rear-most of the car’s trunk.

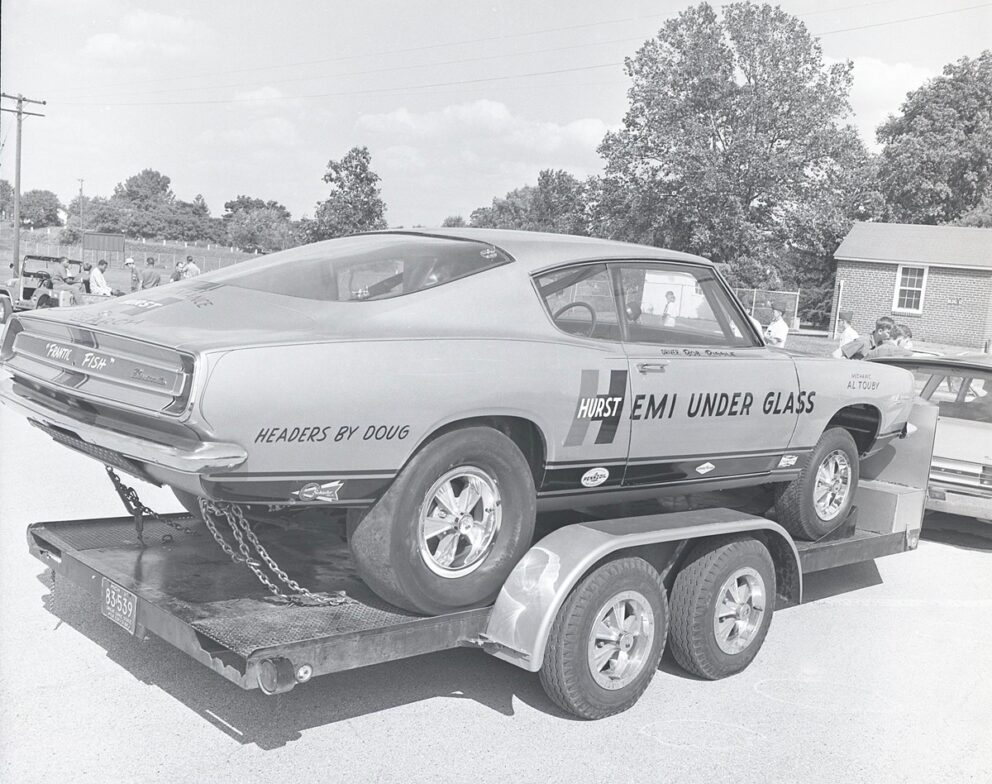

Airheart disc brakes were fitted and to help slow down the Frantic Fish, a 14-foot diameter Deist chute was added along with a set of Hurst 5-spoke forged wheels (now long out of production) and a pair of M&H Racemaster slicks.

The front of the “Bear-A-Cuda” (the car had several monikers!) was slightly raised up via adjustments made on the torsion bar suspension, and the hood and front fenders were treated to a bath in acid to lighten the cars overall weight. Plexiglas replaced the standard glass and in the end, the HUG weighed in at 2,960 pounds, with 1,980 pounds over the rear wheels.

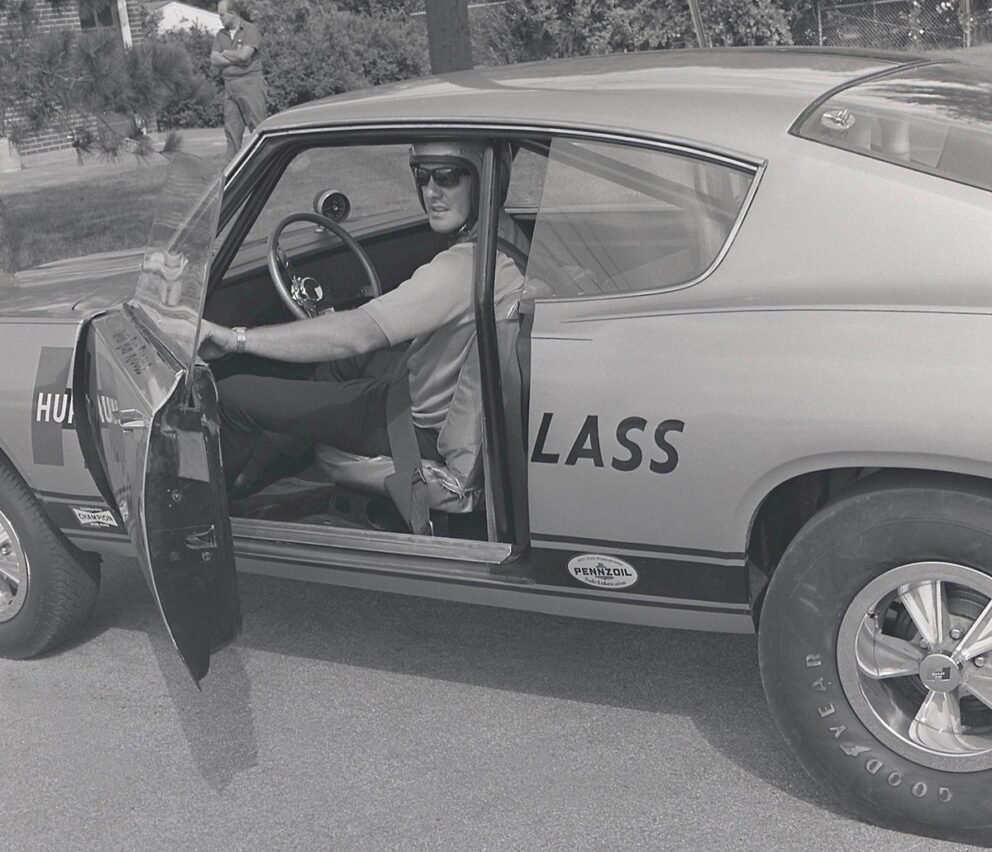

When it became time to find a driver for the one-of-a-kind Barracuda, George Hurst met (while they both were in Hawaii at the time) and contracted Bill Shrewsberry to drive it and this helped him live up to his name “Wild Bill” to be certain! According to Shrewsberry, as far as he knew, the car was originally intended as an exhibition car that would be capable of running in the 9-second zone, however was never intended as being a full-fledged “wheelie car.”

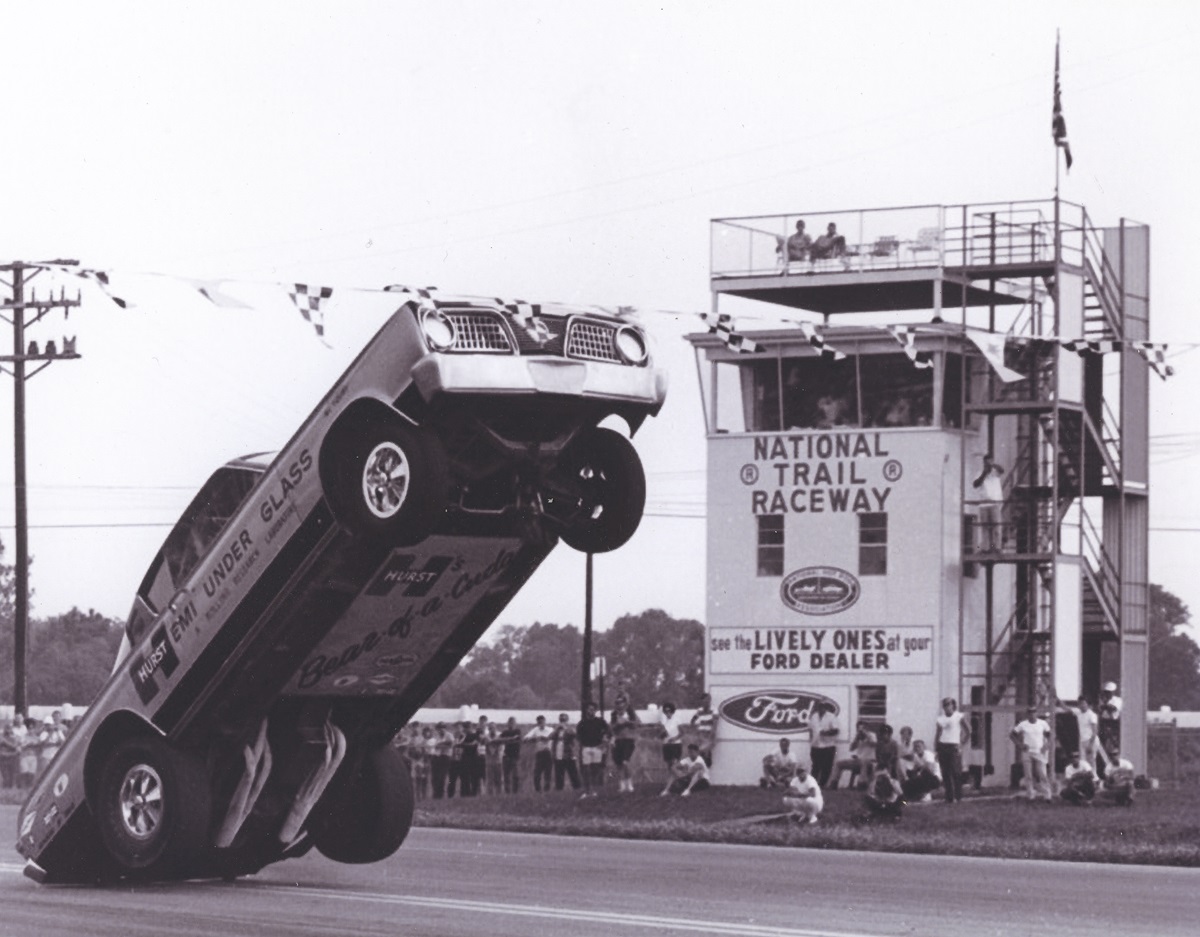

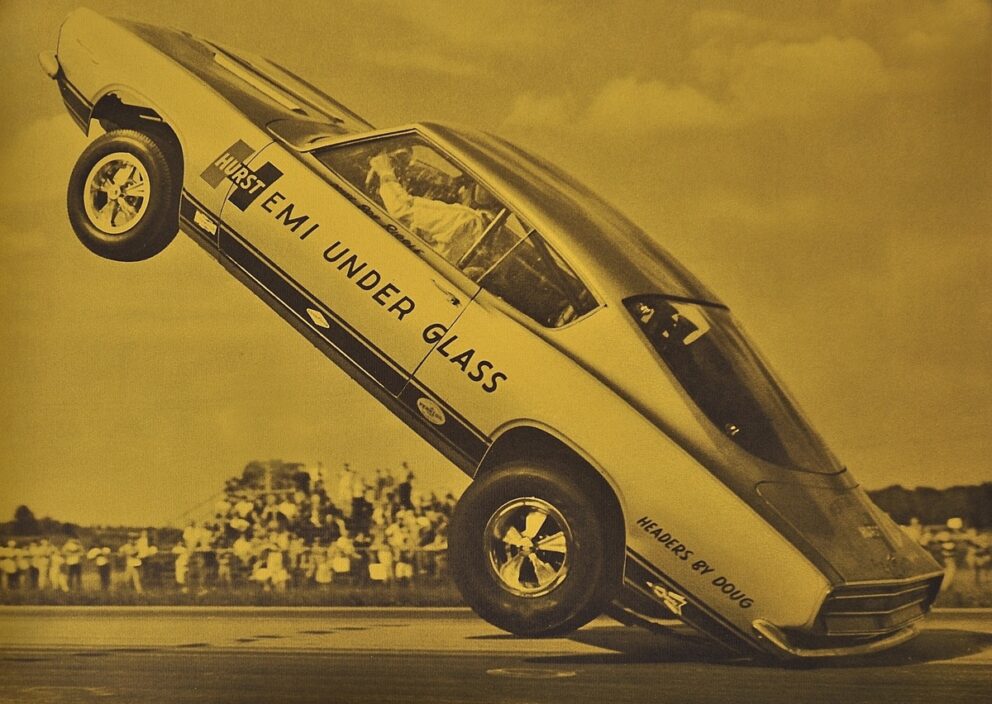

However, with that potent injected HEMI engine in the rear and almost no weight up front, every time the accelerator was mashed, up came the front of the Barracuda much to the joy of the trackside crowd of spectators.

Wheelies are considered to be a primal thing; the art of “pulling a wheelie” goes back to kids riding their bicycles and pulling wheelies for as long as they can. People identified with this wild ‘Cuda and for some 40 years, a Hemi Under Glass car has entertained drag race fans and for those that see the car run for the first time, wheels in the air and sparks a-flyin’, it’s an awesome sight!

After running the car for a short time period, Wild Bill Shrewsberry left the driver’s seat in the Hurst car and went on his own with a Dodge called “L.A. Dart.” The replacement driver for Hurst was employee Bob Riggle. Riggle quickly became a talented wheel man and mastered the art of running high speeds on just two wheels, part of which includes using a separate lever to control the rear brakes (independently, left and right) to keep the Barracuda straight as it travels down the track.

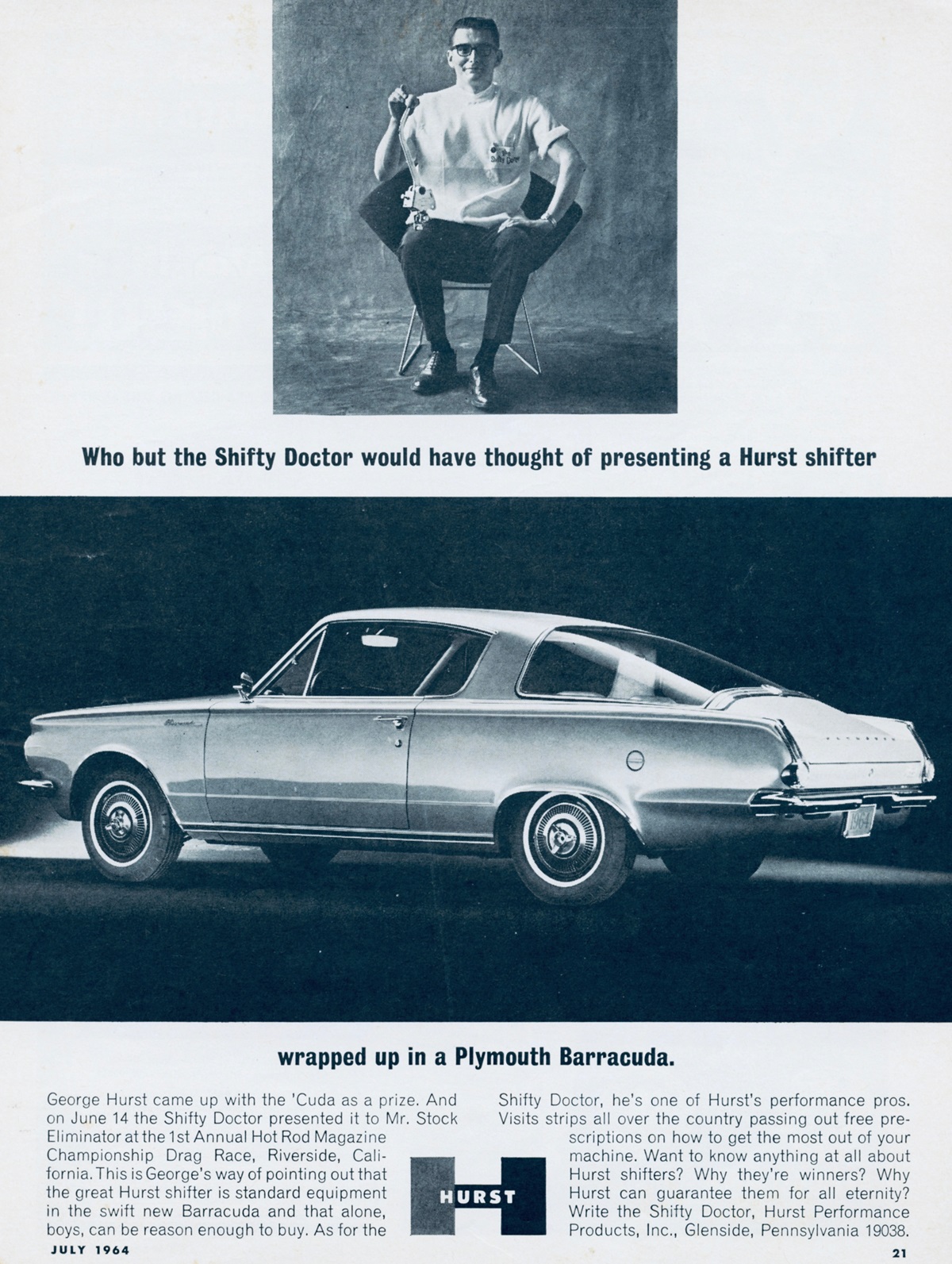

SHIFTY DOCTOR BARRACUDA AD

For 1964 Barracudas, when the optional 4-speed transmission was ordered, it was fitted with a Hurst shifter. As a special promotion, Hurst gave away a new Barracuda as top prize to “Mr. Stock Eliminator” in the inaugural Hot Rod Magazine Championships at Riverside, CA, which was Gas Ronda and his Thunderbolt.

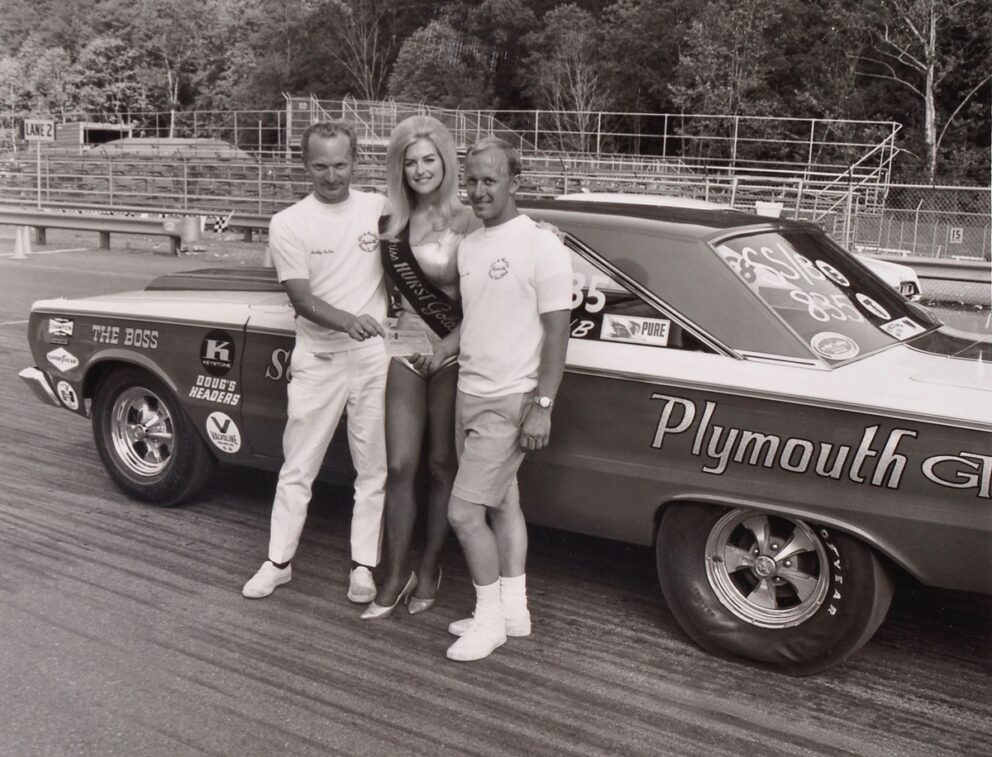

THESE TWO GUYS STARTED IT ALL

The idea of converting the sloppy and difficult to “speed shift” column shifters on cars of the day to that of a floor shift design caught on quickly. The factory-stock “spaghetti” linkage wasn’t all that great for racing applications, and George plus his assistant Bill Campbell (who later became an equal partner) came up with a much superior design for floor shifting that allowed for fast shifts and that was very durable. The very first design in the beginning stages had the signature curved, flat-shaped chromed shifter lever with, at first, a “yo-yo” type handle, then later the white-hued “cue-ball” round handle was added and changed the automotive world forever. These men perfected the shifting mechanism on the line of shifters which provided precise operation and bulletproof long-lasting performance. Combined with a top-quality shifter was the threaded adjusters on the linkage, which gave accurate adjustments as a result of .040-inch increments with each turn on the threads. Selling Hurst products was one of the speed shop businesses that the counterman never had to worry about product returns because of inferior quality.

“I came from nowhere and I’m not afraid to admit it,” George started out. “It wasn’t easy, and it still isn’t.” He told of a cold, gray winter day when he was out making sales calls in his battered ’56 Chevy, that had no heater (and a lot of holes in the flooring) and he was about to begin a cross-country trip to sell his wares. “I damn near froze to death, I stuffed dirty clothes in the holes to keep out the cold. That’s how bad it was. Once in the Midwest, I was entering a turnpike and the signs said ‘Chicago and West’ and ‘Cleveland and East.’ I sat there for a few minutes fighting the temptation to turn east and give the whole thing up. No one will ever know how close I came,” George shared in the interview.

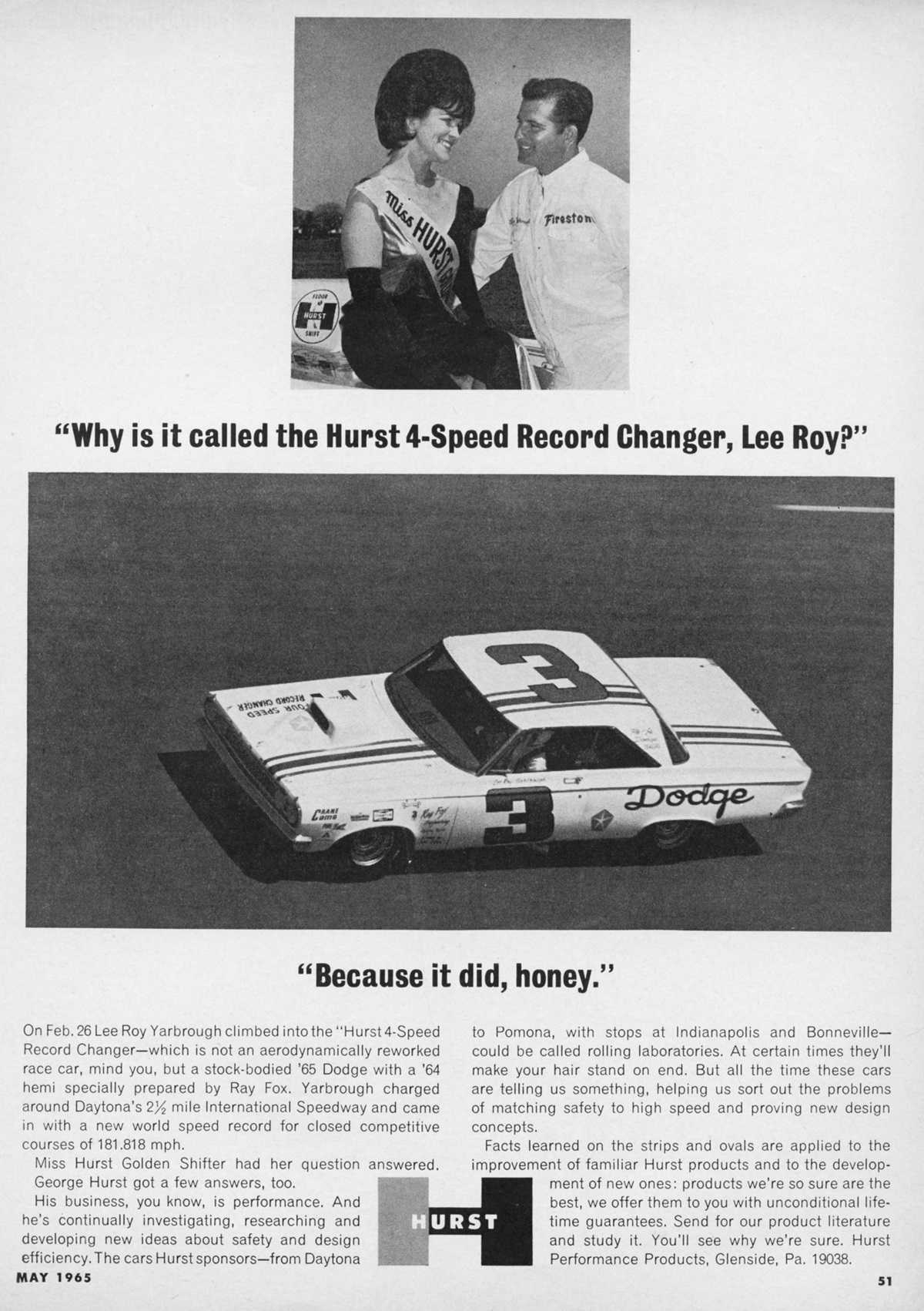

Another Chrysler-specific early advertisement was the Lee Roy Yarbrough ’65 Dodge NASCAR car full-pager, shown in the ad is Patty Flannery Stephens, the first “Hurst Miss Golden Shifter.” It celebrated the 181.818 mph world record run that took place on February 26, 1965, a HEMI engine-powered hardtop prepared by Ray Fox. Hurst shifter equipped!

ALL-NEW WHEELSTANDER FOR ’67

For 1967, a new Barracuda was built, and it was now painted gold with retaining the Hurst wheels. “It was a new body and I constructed a new subframe,” shared Bob Riggle in a Mopar Muscle 1993 interview. “We did take the drivetrain out of the older car. The only change I made was that I would occasionally run five percent nitro in it, which gave me a little more speed.”

The Hemi Under Glass oftentimes performed for the Armed Forces and at times would give rides to soldiers, something that of course was an experience that made for everlasting memories. Bob Riggle would drive and set up the car (along with mechanic Al Touby), plus at times, George Hurst would also attend such events!

As speeds increased with the ’67 car, it was decided to add a feature that would help insure the Barracuda go down the track as straight as possible. “I decided to put steering brakes on the car,” Riggle continued in the interview. ” So I went to Bob Airheart and Hurst/Airheart and asked what they had. He set me up with a pair of dual brake calipers. I also had to get approval from Hurst and they didn’t really want to do it because they thought we would go too fast! But I convinced them it would be more reliable and the cars would be less prone to go over the centerline or into the guardrail. Now we would be able to actually steer them.”

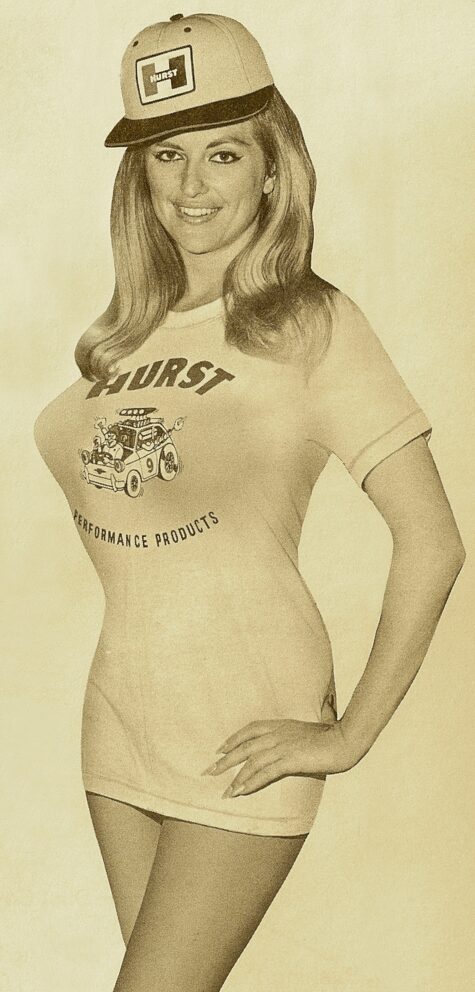

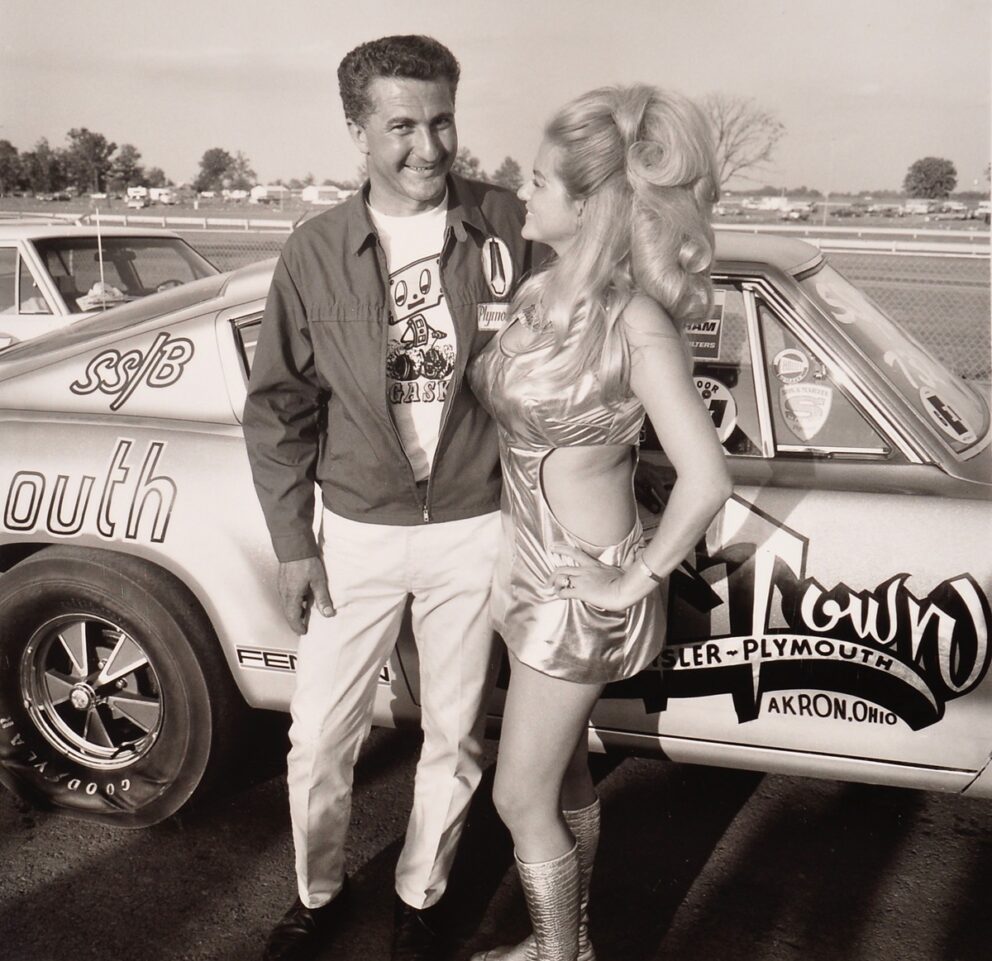

MISS HURST: LINDA VAUGHN

George Hurst had used women to help draw attention to his shifter manufacturing company during the mid-1960s (both Pat Flannery Stephens and Jenene Walsh had served as “Miss Hurst Golden Shifter”) and he had made a decision to get a new woman to do this job for the 1966 racing season. A full-page advertisement announcing a competition for this position was placed in Hot Rod Magazine and it described what the company was looking for: an attractive, warm and friendly, outgoing and knowledgeable spokes-model and with good teeth.

Vaughn called George (whom she had gotten to know from the races) and he suggested she enter the contest, so it was off to California. Of course there were several other beautiful women vying for the job of being Miss Hurst, however Linda did something that was rather smart and it showed her sincerity in her desire to get the position, she made a formal business presentation to the Hurst Performance Board of Directors the night of the final judging, telling them how she was going to not only perform as the race queen but also how she was going to make the Hurst name greatly more famous than it currently was by getting more exposure for the product through her experience in the automotive circles. It worked!

She immediately let everybody know that she wasn’t George’s girlfriend and that she didn’t “mess around with anybody that works for the company” and that basically business was business. And Linda is a true fan of high-performance, she has long loved racing cars of all types, from NASCAR stock cars to NHRA top fuelers and on to Pro Stocks and Indy cars, Trans-Am, Can-Am, Baja race vehicles and everything in-between over the years. “The greatest sound in the world is a racing engine, from a rough idle to full power…any kind from a boat to a fuel dragster…and the greatest sight is a background of 10,000 people, like at Daytona, and a flock of cars tight at 180 or a pair of fuelers smokin’ to the Nationals finish line,” she said in an early interview. Her job of promoting Hurst was done in a fashion that was, as she described being “sexy but not sexual.” She was a Georgia Peach in the eyes of everyone who saw her.

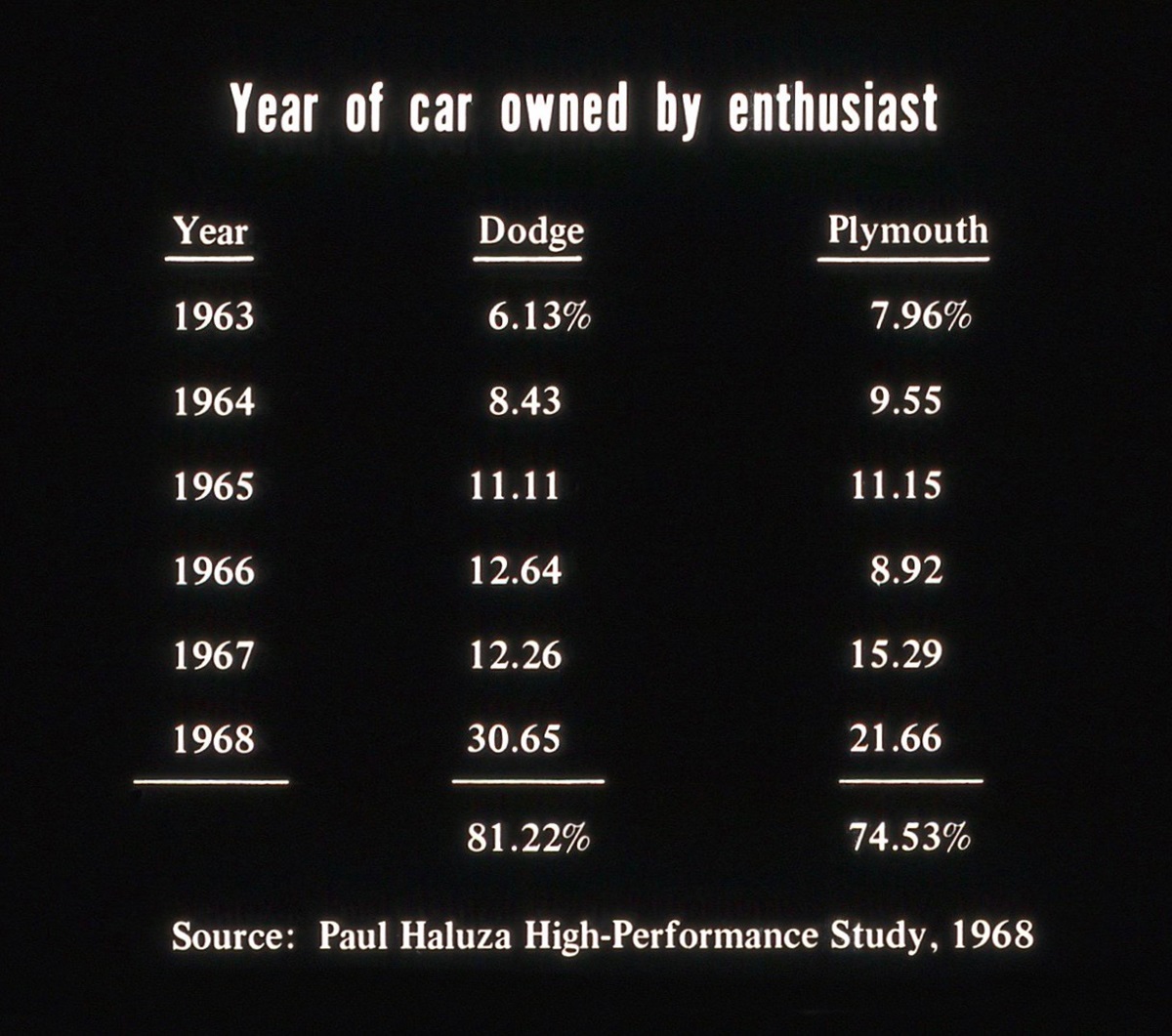

IMPRESSIVE NUMBERS IN HURST STUDY

When Paul Haluza’s 1968 High-Performance Study was done for Hurst explaining the increasing numbers for Dodge and Plymouth vehicles, it was very encouraging for upper management. From 1963 to 1968, the percentages of ownership for these Mopar vehicles were listed at over 81 percent for Dodge vehicles, nearly 75 percent for Plymouth vehicles. Muscle cars were hot on the streets of America and it was well worth the efforts from Hurst to focus on Chrysler products.

Speed shops all across the country had on-hand Hurst inventory of not only the actual shifters for Mopar vehicles, but also in addition the upgrades and accessories. T-handles were super popular to say the least.

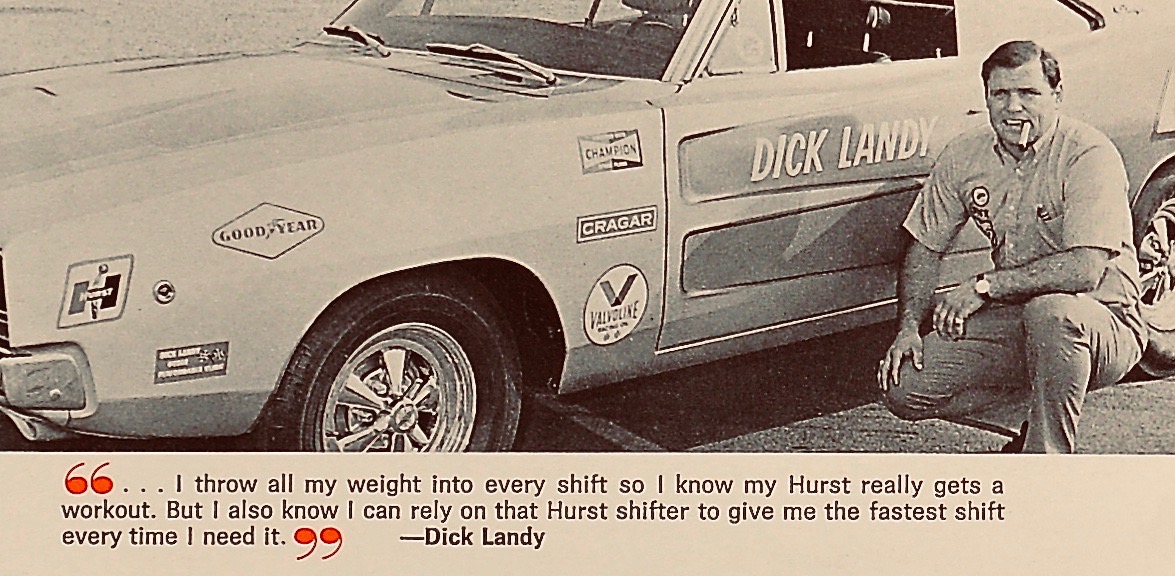

DICK LANDY

“Power-shifting” was what Super Stock drag racing was all about for manual transmission cars, and Dick Landy was one of many that ran Hurst shifters! Even if they ran an automatic, Hurst shifters were used for precise shifting through the gears.

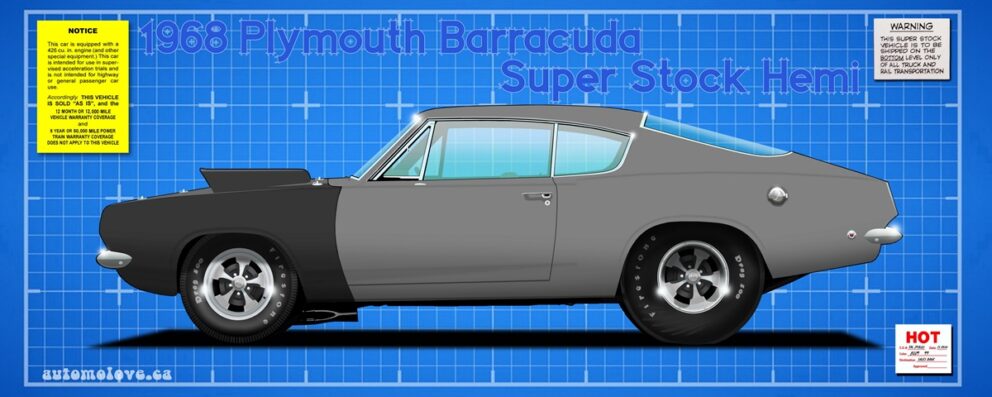

HEMI DARTS / BARRACUDAS FOR 1968

In order to produce these special purpose-built 168 drag cars, the Dodge Darts and Plymouth Barracudas, fitted with 426-cid race HEMI engines, Chrysler turned to Hurst to make it happen! The HEMI conversion project was coordinated by Dick Maxwell from Chrysler, and Dick Chrysler from Hurst. Dave Landrith handled much of the sales effort, and the work was done by the Hurst Performance Research division of the company. Pictured is a Dart that showed the primered body, gel-coat fiberglass front fenders and hood, along with the stock wheels and tires (which would be replaced by the individual racers with race rubber) as well as an artist rendition (Robin McQueen) of the Barracuda version, drawn with a set of typical aftermarket wheels (Keystone Klassics) and race-spec tires.

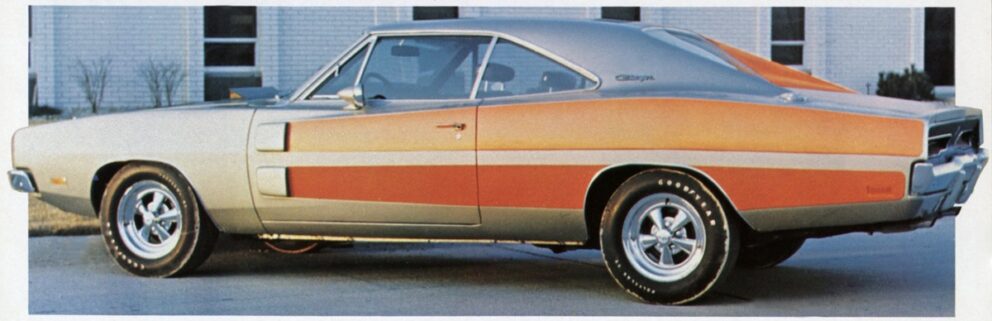

PROPOSED 1969 CARS FROM HURST

There were two different Dodge Division proposals from Hurst, a Bright Sun Rise Yellow 383 “Hurst/Dart Swinging Bee” with multiple bumble bee stripes, Cragar S/S wheels and hood scoop.

The Charger was a 440 car to be called “The Hurst Medera Charger” featuring vacuum-operated hood scoop, unique front lower fascia, side scoops, Cragar S/S wheels and custom paint treatment. In both cases, obviously Hurst shifters were part of the packages.

While there were prototypes built to show the Dodge management team, the projects never went on to see production.

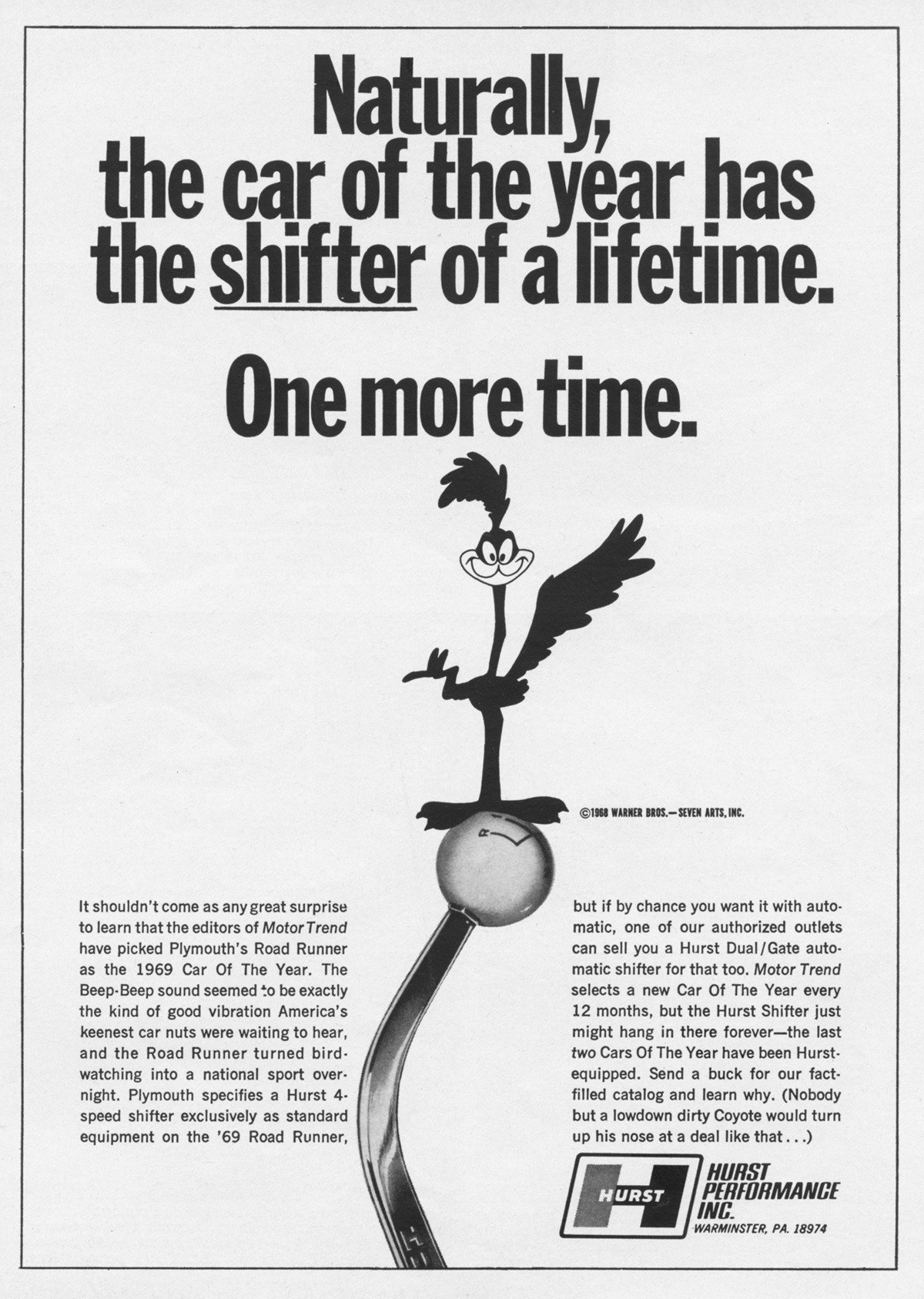

ROAD RUNNERS HAD HURST SHIFTERS!

To help celebrate the announcement from Motor Trend Magazine‘s awarding the 1969 Road Runner as their Car of the Year, Hurst ran this full-page ad in the automotive enthusiast magazines. Hurst 4-speed shifters as OEM installation, and if the customer opted for an automatic, Hurst could sell them one of their Hurst “Dual/Gate” automatic transmission shifters.

Part II is all about the Chrysler 300-H for 1970, the famous “Pistol Grip” Hurst shifters, Hurst large-diameter wheels, and specially-built Hurst Vipers, Challengers, Chargers, Chrysler 300s and Dodge Trucks.

Author: James Maxwell

0 Comments