You Can Weld, But Should You?

YES!!

Ever since I started turning my first wrench on a car, I have always had the desire to be able to do anything and everything possible myself. Repairing the mechanicals, rebuilding motors, fixing a dent, painting, restoring a trim piece, weld a broken metal component or fabricate my own cool stuff, service the HVAC system or do any alignment. Some of those goals might just be wishful thinking simply from a financial aspect. Trying to outfit your shop or home garage with a paint booth, metal fab and welding equipment, and all the more conventional mechanic’s hand tools is well into the six figures or more.

Welding was one of the skillsets I seemed to really gravitate towards for years. I never pursued doing anything about it because the cost of the equipment was high and (pre-internet/YouTube) how in the heck would I even learn how to do it. Knowing nothing about it left me overwhelmed and confused anytime I would look into trying to figure out where to start. Plus, let’s face it, you generally don’t need to weld for most typical automotive mechanical repairs. The return on investment never seemed to make much sense. Fast forward past college and into young adult life and homeownership and I find myself picking up a 1950 Plymouth project car. I found it for sale in a field 2 hours from any civilization, at night, and called the following day and snagged that baby for $1,500. I had a tow truck go pick it up and take it to my house. It looked great! I was hoping for a little bit of mechanical work and maybe a new fuel tank and brake overhaul and I’d be on the road cruising. After noticing a few suspect concerns, I began stripping the car down and found more holes and rust than good metal. I guess now is the time where I could have used that welding skillset. A good friend of mine who happened to be a great welder said he would give me some pointers. The love story began there.

Oh, how I love thee, my melting hot molten alloy blob. Your sparks of desire are electric. Let me bond thee for eternity with an unbreakable bond. Like Tom Hanks in “Castaway” in the iconic bonfire scene, “Look what I’ve created, FIRE!”.

On one hand, welding is extremely complex and expensive and insane. On the other hand, it’s very simple and affordable. To keep it light and not overwhelm anyone, I’m going to keep this very generalized and not get TOO deep. The fact is, welding is more affordable than ever, and easier to learn than ever thanks to the good ole internet. I think you will be surprised how cheap it is to get started and how easy it is to learn yourself and be on your way to melting metal together! I’m going to try to break it down to basics for you so you can navigate your way to learning how to weld yourself. My goal here is not to teach you how to weld, but rather, get you pointed in a direction and try to remove some of the clutter and confusion, so you don’t get frustrated or overwhelmed.

Again, generally speaking, regarding automobiles at least, there are two main types of welding processes. They are both similar, but different, and do the same thing, and do different things. Ahhh crud, it’s already getting messy. Both these welding processes have some basics in common though, and that is what you should focus on. Welding is the process of joining two pieces of material together through heat or pressure. Most of the time, people are referring to welding with heat. In our case here, we are sticking two pieces of metal together with heat. The process melts the metal into a molten state and as it cools, they are now joined like peanut butter and jelly. I must point out again that I am keeping this very general so you don’t get overwhelmed and clouded by too much detail. In most cases, welding uses electrical current to heat the metals to their melting point. If that confuses you, picture a spark plug and that beautiful blue arc that jumps off it.

There are some inherent scientific hurdles in that process that are overcome differently based on what type of welding machine or process you are using. The biggest factors in that are what types of metals you are welding and shielding the weld from the atmosphere. The same air we breathe will ruin a weld if it makes its way to the weld before it cools. The direct area that is being melted must be shielded from the outside air. The way in which it’s shielded varies depending on the type of welding process being used.

So just to recap, we need a machine that can use electricity to focus and pinpoint that energy into a piece of metal, shield that beautiful and tiny melted pool of lava until it cools, and do so continuously and seamlessly.

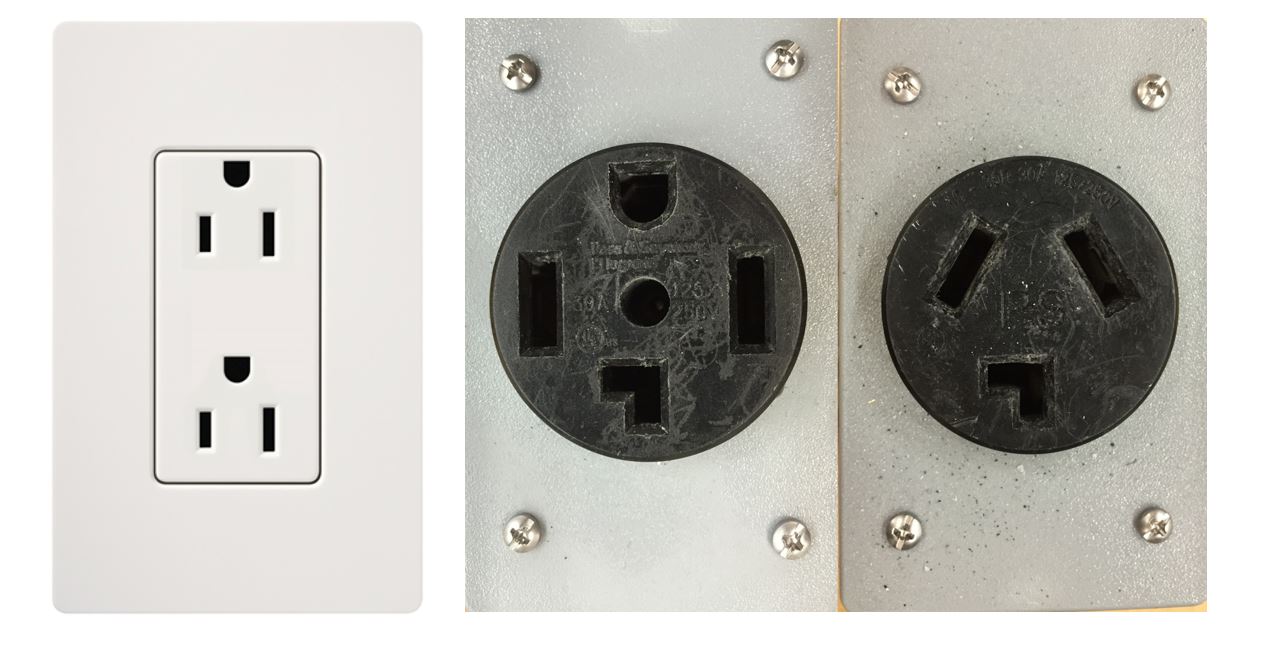

Before you even get into what type of machine you want to consider purchasing, first consider what type of electrical supply you have available at your house/garage/shop. Welders come in a variety of voltages, and sometimes dual voltage. Usually, the lesser expensive machines will only operate on 120V, or any outlet in your house. This allows for somewhere around 100-140amp welding depending on the machine. The higher the amp rating of the machine, of course, indicates the hotter it can run, and thus the thicker the metals you can weld. Most of the sheet metal on a modern car is well within the thickness that most 120V machines can properly weld on. Once you start getting up past 1/8” thick material, you will likely need a 208/240/480V machine. The good news is that most people’s homes have a 240V outlet or two. The majority of home laundry dryers and oven/range run on 240V. With the proper materials, you can cheaply and easily make an extension cord to run from your dryer or range outlet to your garage (if the distance is within reason). Most hardware stores carry the proper cording and plug ends to make one up on your own. In this article, we are going to go over MIG welding. Next time, we will cover TIG welding and multi-process machines.

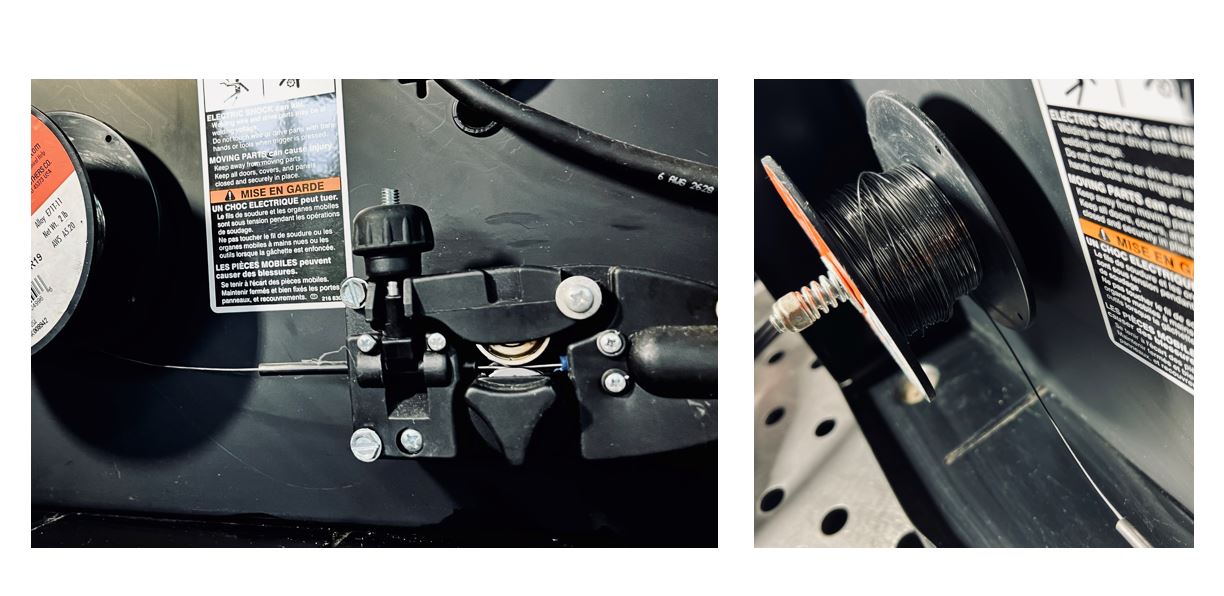

MIG Welding: MIG welding is probably the more common type of welding that you encounter when working with steel and automobiles. Luckily for you, it just so happens to be the easier one to learn and cheapest equipment to purchase. MIG stands for Metal Inert Gas. Don’t really focus on that. Here is what you should know. A MIG welder can be purchased online or at big box retailers all over the country. They can range anywhere from $100 to several thousand dollars. Sure, sometimes you get what you pay for. If you aren’t using a welding machine to make a living and using it hours a day, I don’t see any reason why you need the most expensive one on the market. MIG welders have the main body, a spool of wire, a ground clamp and a “torch”.

Inside the welder there is a large spool of metal wire. Think about it as being similar to a roll of solder, but larger. It is fed through some sort of motorized feeding system that spins the spool, so the wire comes out the end of the torch continuously.

A ground cable run from the machine to the metal you are welding and DC electrical current run through the wire creates an electrical arc at the point of contact, just like touching your jumper cables together before you stick them on your friends’ ears.

Within MIG welders, there are a few things that can differ between machines or types of machines. As I mentioned prior, the weld pool (the area of melted metal at its hottest temperature) must be shielded from outside air. There are two different ways this can be done with MIG welding. The first, and most basic and least expensive type of MIG welding machines is “flux core”. Flux core welding machines use a spool of wire that has welding flux inside of the wire. Very similar to using flux when soldering, the flux inside the welding wire keeps the weld area clean and helps shield it from the outside air and contaminants. Spools of wire are inexpensive, and the machines are simple to set up and operate. If we were to compare a flux core MIG welder to something like a firearm, think of it as being a shotgun. Good for a lot of things, a bit messy, not a lot of features, anyone with a brain and a hand can use it, and it usually gets the job done. The other type of MIG welder is not much different than a flux core MIG welder. Instead of using flux core wire, it uses a separate tank of shielding gas that is hooked to the machine which feeds gas through the torch alongside the wire. The gas exits the nozzle of the torch surrounding the wire, arc and weld pool. It’s a much cleaner and controllable weld. The type of gas varies based on application but is most commonly Argon or C02 mixture. You can rent tanks from local supply houses or purchase your own and simply pay for the refills. The gas is inexpensive and will run somewhere around $30-40 for the smaller sized bottle. Its as easy to unhook and refill as your propane tank on your gas grill.

This type of MIG welder is probably the more preferred process as the shielding gas provides a cleaner and more controlled weld than the rather sloppy flux core welding. Most machines that run a shield gas tank can also run flux core wire as well, so you have the ability to switch back and forth if you want. There are not a bunch of settings to figure out on most MIG welders. You usually have an on/off switch, a wire feed control and a power control. The wire feed control sets how fast the wire is fed from the torch. The power control sets how “hot” or how much current is being sent through it. There is some science and art to learn how to set those two settings in relation to each other to get the results you want.

Although, so far, there seem to be a lot of positives for MIG welding, but there are some cons. Like I mentioned, flux core MIG welding is that of a shotgun. It is the sloppiest of welding processes. The wire feed works great … when it works great. Wire feed issues can be common depending on the quality/price/usage of the machine you have. Nothing is more frustrating than getting started on a weld and just seconds later it all starts sputtering and dies on you. Sometimes, the feed wire can get jammed or bind up inside the torch cable, or the rollers in the machine that feed it slip and don’t feed the wire continuous. The other big con is that MIG welding is a one-trick pony in a sense. Without getting too deep, MIG welding, especially flux core MIG welding, is only usable with steel. Regular ole, boring, plain, mild steel. Most of the time, you don’t/can’t use a MIG welder for aluminum, stainless steel, or any other type of high-end metal or alloy. This is a generalization here, because it is possible to weld those metals with a MIG welder, but it requires a variety of other considerations/kits/combinations and, in general, is not the most effective way to weld those materials and achieving great results.

MIG welding is arguably the cheapest and easiest to learn. My suggestion is to start with MIG welding if you have any interest in venturing into this world of welding. If you can afford the additional price of getting a machine with gas hook-up and the consumable cost of the gas, that would be the way to go. My first MIG welder was a flux core only machine, it cost $120 brand new and lasted me TEN years! It, and/or I, didn’t make the most beautiful welds with it but it definitely got the job done. The wide availability and variety of machines out there makes them affordable and easy to get. There are plenty of resources online for learning the basics of MIG welding fairly quickly. Getting good at it just requires practice and practicing/following proper methods and techniques. I may not have pulled it out on a daily basis on all the days I spent turning wrenches doing mods or repairs, but it certainly got put to use. Having the machine and the ability to use it even in the sloppiest and most basic ways gave me the feeling of being that much more equipped to tackle projects. The price point and resources to learn definitely puts it on the list of must-have tools/skills for every gear head out there.

There are a few other items you will need to get started welding in addition to the machine. Oftentimes, you can find kits or packages with the welder that include these items. You will need a welding hood to use 100% of the time. They come in all shapes and sizes and prices. The brightness of the electrical arc from welding can damage your eyes or blind you in an instant. These specially designed pieces protect your eyes and face from the volcano eruption just inches from your face. It’s a dark-tinted lens that is so dark you almost can’t see out of it in regular light, but the extreme bright arc while welding is visible as if you were wearing sunglasses. I recommend an auto-darkening version. While not welding, it’s similar to wearing very dark sunglasses. Once you start welding, within milliseconds, the lens automatically darkens and turns almost black, so that it’s now at the same level and a regular welding lens.

This makes getting your hands and materials in position much easier with the ability to actually see what you are doing at the moment you start your arc. You will also want some leather welding gloves. As mentioned previously, we are dealing with a crazy amount of heat. Go with what feels most comfortable, and ones rated for welding. You generally want to clean or prep the areas you are going to be welding before you start, so at a minimum I suggest some cheap wire brushes or Scotchbrite pads to clean any oil, scale, debris from the metal. Welding of any sort has the ability to, and will, give you the equivalent of the worst sunburn you have ever had, even after just a few minutes. There are a variety of welding-specific sleeves, jackets, aprons and more to protect your entire body. Do me a favor, at LEAST make sure your arms, neck and face are covered with at least a shirt!

A quick recap:

MIG Welding Pros: inexpensive to purchase the equipment and supplies, easiest method to learn, great for cars with most metals being mild steels, easy setup and use, available supplies/equipment just about everywhere, and 120V units will work for most automotive projects

MIG Welding Cons: ONLY* usable on mild steel, often the messiest/sloppiest/least precise welding method, wire feed jams can be a frustration, you don’t have a ton of adjustments and fine tuning of the weld process, and recent market flooding of imported and no-name brand machines that look fancy and nice often are very poorly made. Do your research.

In part two of this article, we will cover the 50-cal, long range, special-ops, sniper rifle of welding: TIG welding.

0 Comments