GEN II HEMI® Heritage

– Designed in 1963, a masterpiece race engine for NASCAR and drag racing

– Tom Hoover, Bill Weertman, Frank Bialk instrumental in the engine layout

– Still today an icon powerplant on the dragstrip

WHAT DOES HEMI MEAN?

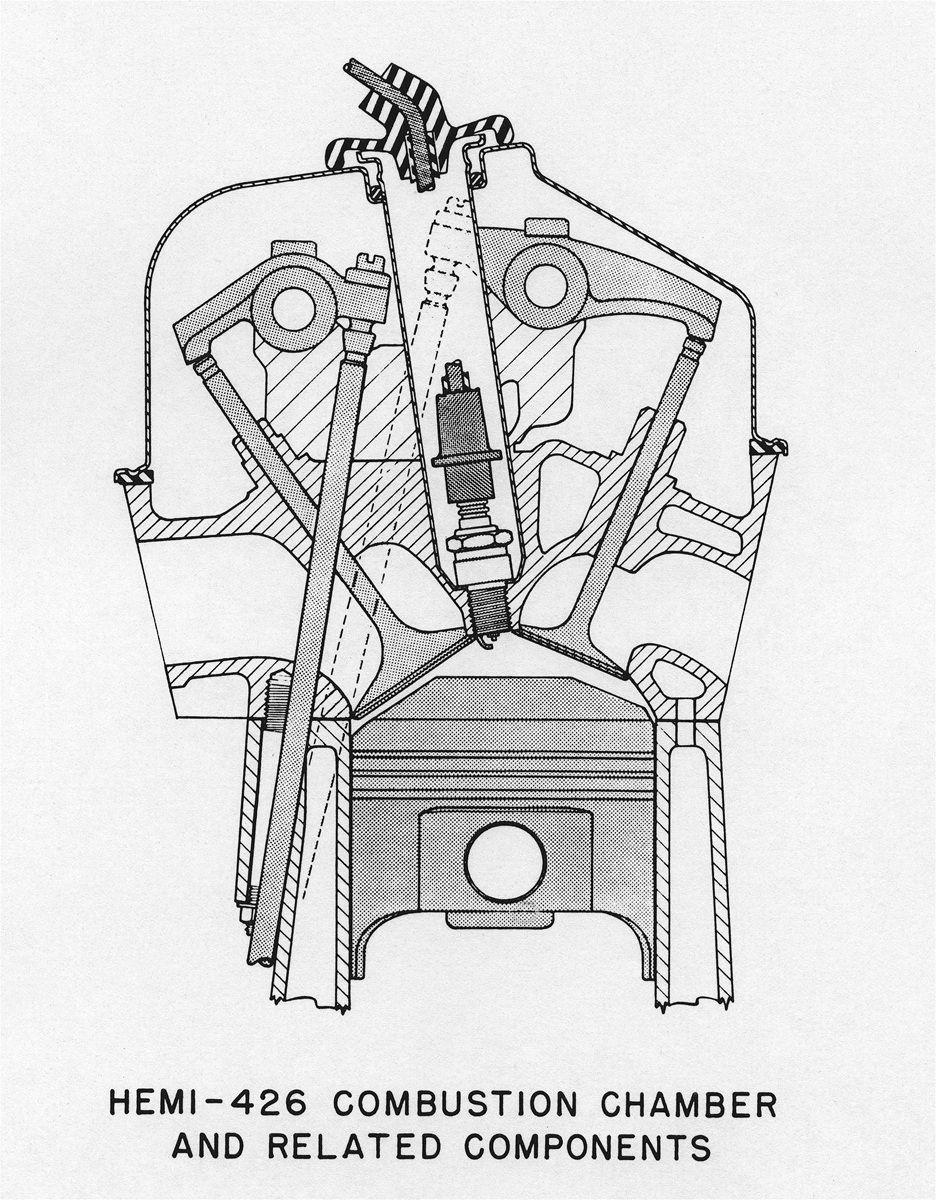

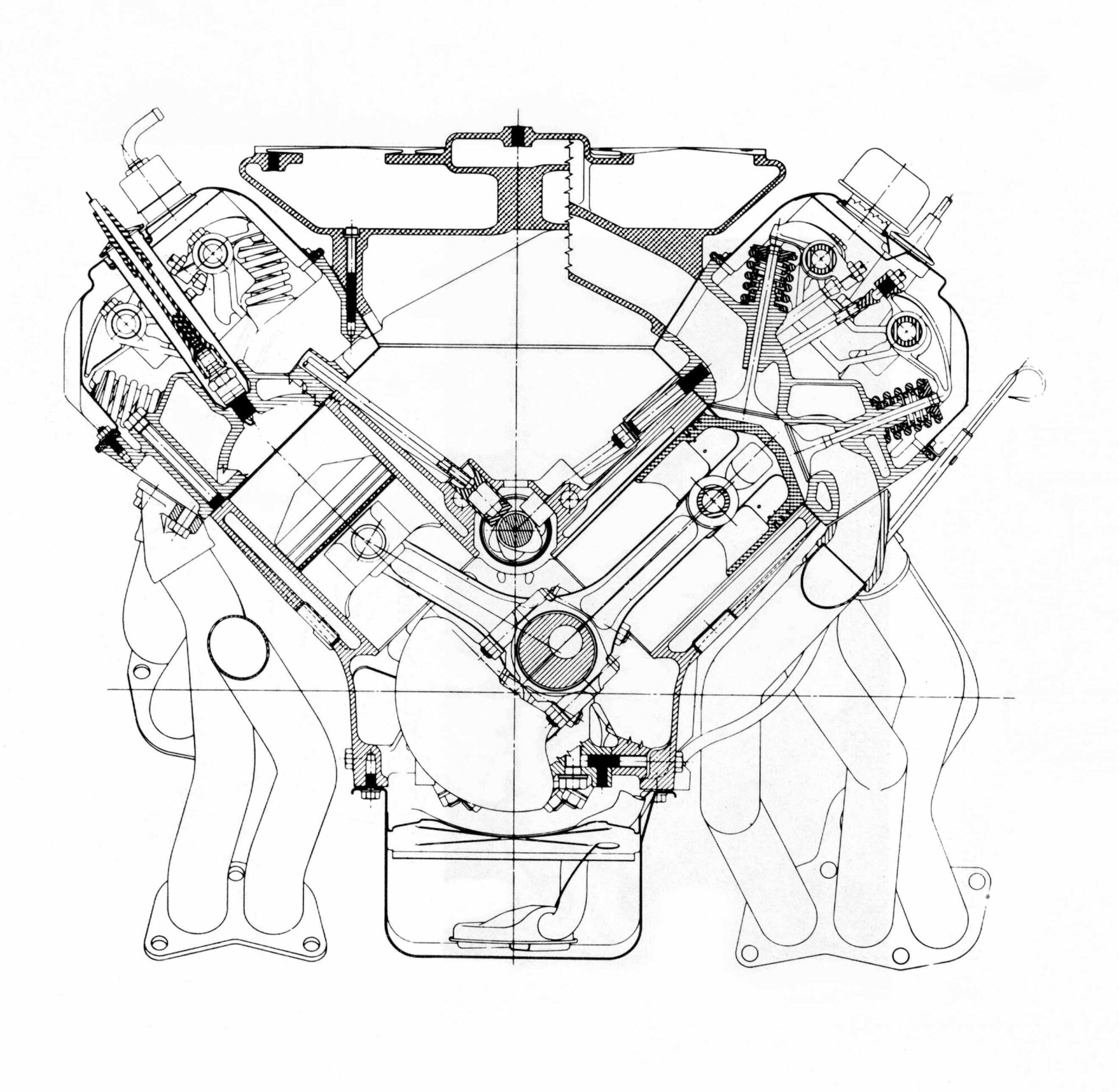

By definition, the word “HEMI®” (short for hemispherical) means “one half of a sphere, formed by a plane that passes through the center of the sphere.” In the case of Earth, its northern and southern hemispheres are separated by the equator. In the case of a cylinder head built using a hemispherical design, the combustion chamber is like that of the inside of a dome. Seen in a cross-sectional view, a hemispherical cylinder head looks like the upper half of a terrestrial globe, with the flat area of where the head gasket is located representing the plane that passes through the center of the sphere.

The buzz about a new version of the Chrysler HEMI engine first surfaced publicly in the pages of Popular Hot Rodding Magazine (December 1963 cover date) with these words from writer Greg Curtis: “When another engine comes along to replace the old ‘HEMI,’ and matches its performance, it also will have hemispherical combustion chambers. This is the only way to go for ultimate breathing. Chrysler engineers know this very well – (even though they replaced the HEMI with the wedge-chamber ‘B’ engine). This will be proved next spring when these same engineers introduce a brand new set of HEMI heads for B Super/Stock engines! That’s what the grapevine has been saying.” There had been talk for a while about Chrysler bringing back the HEMI engine, but this published report is believed to be the first real teaser about it, perhaps planted by a Chrysler PR man.

Curtis’ article was titled “Chrysler is King” and he points out the then situation for hot-rodders regarding the out-of-production FirePower engine. “The big HEMI-head Chrysler is dying a slow death. Or rather it’s being strangled. Chrysler quit building the things in 1958, because of excessive production cost. Parts are still available – but they’re getting tighter every day. The factory warehouse supply of brand new blocks and heads was exhausted long ago. The boys who are running Chryslers today are living off junkyard parts. Of course this can’t go on forever.”

Looking back, writer Greg Curtis obviously was given an accurate tip off that the new HEMI engine was coming from Chrysler, and while he didn’t have any specifics on the new mills, he assured his readers that “it will take another HEMI-head design to take its place (the FirePower) in the hot rod picture.”

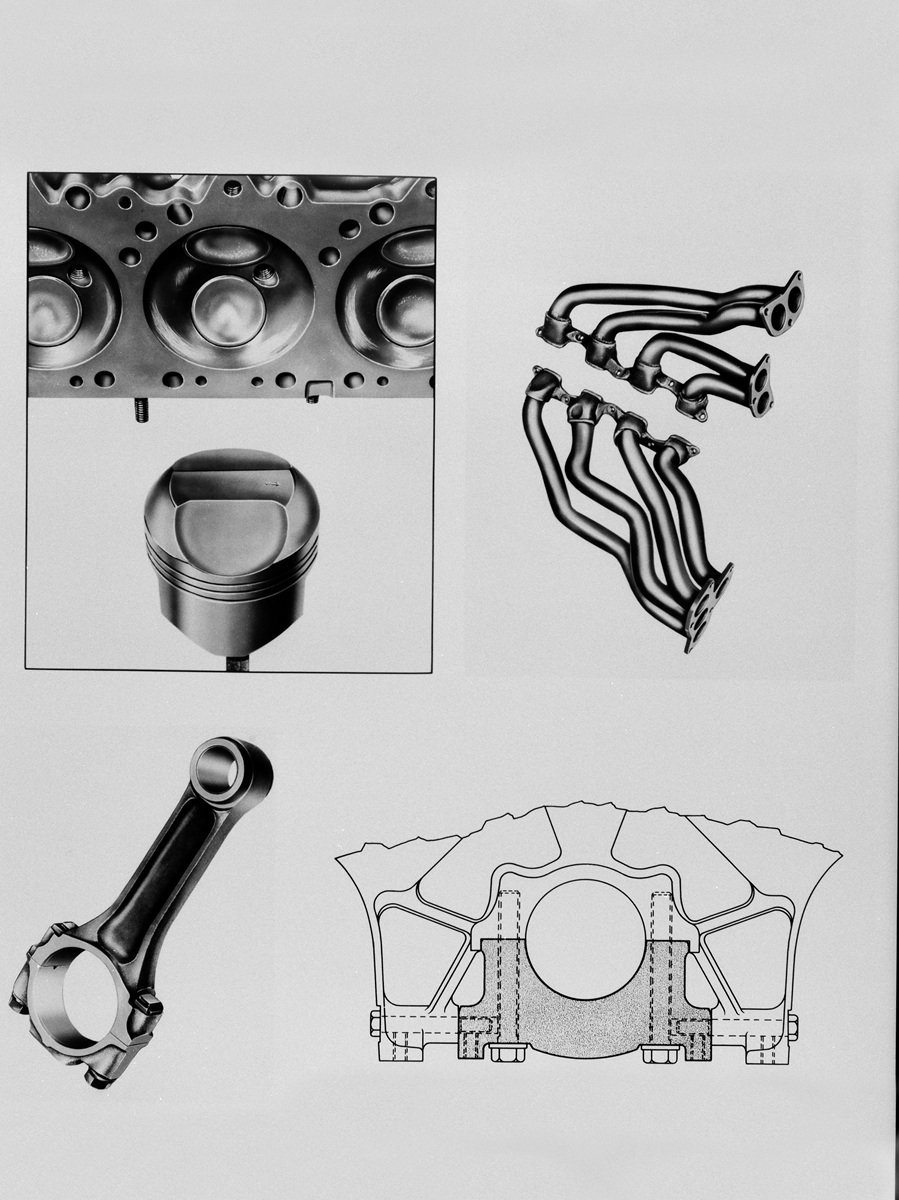

Among the components on the new HEMI engine were high-dome pistons, tubular exhaust headers, newly designed, stronger connecting rods with 7/16-inch bolts and main bearing cap with horizontal tie-bolts.

CIRCUIT RACING ENGINE

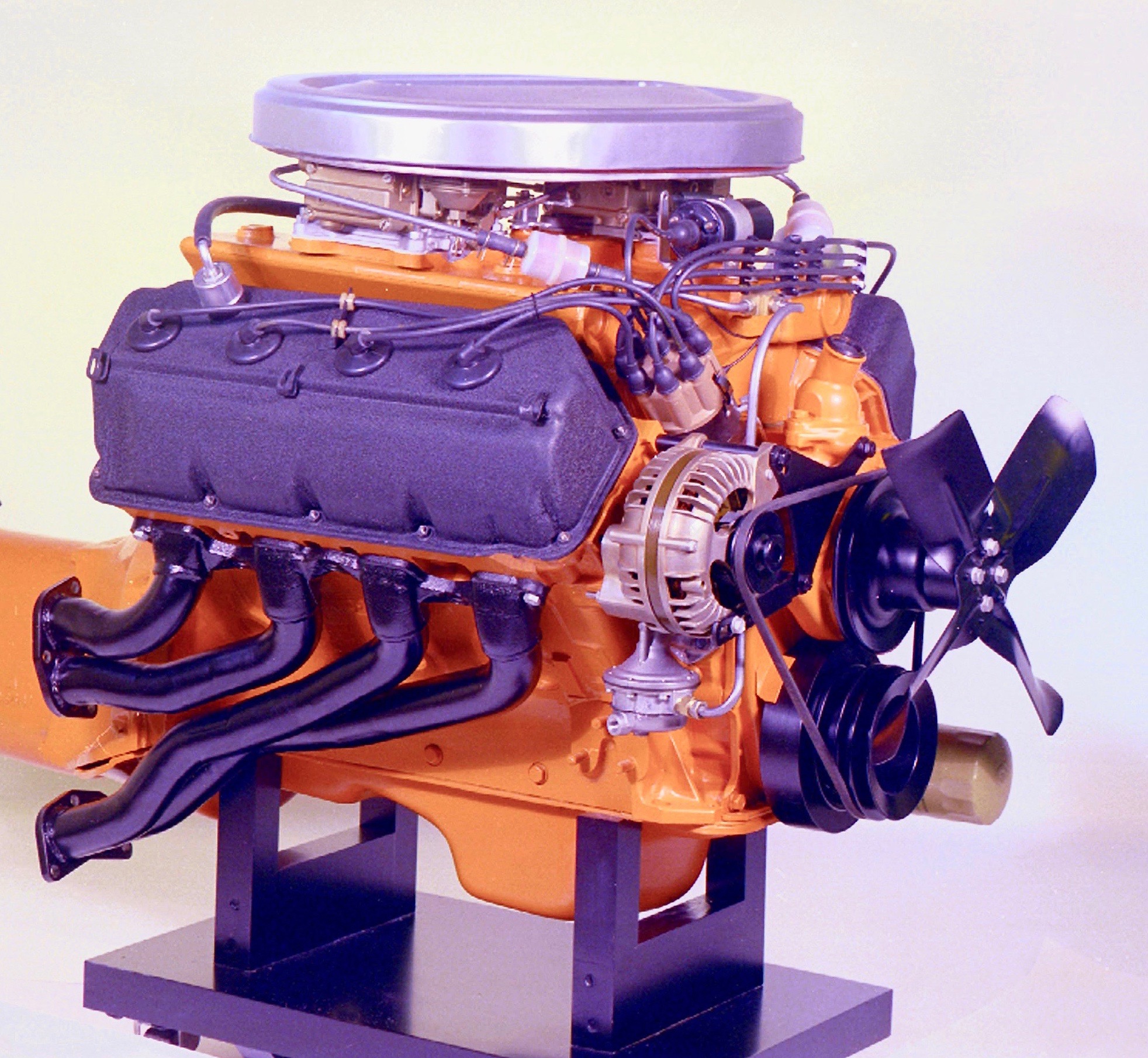

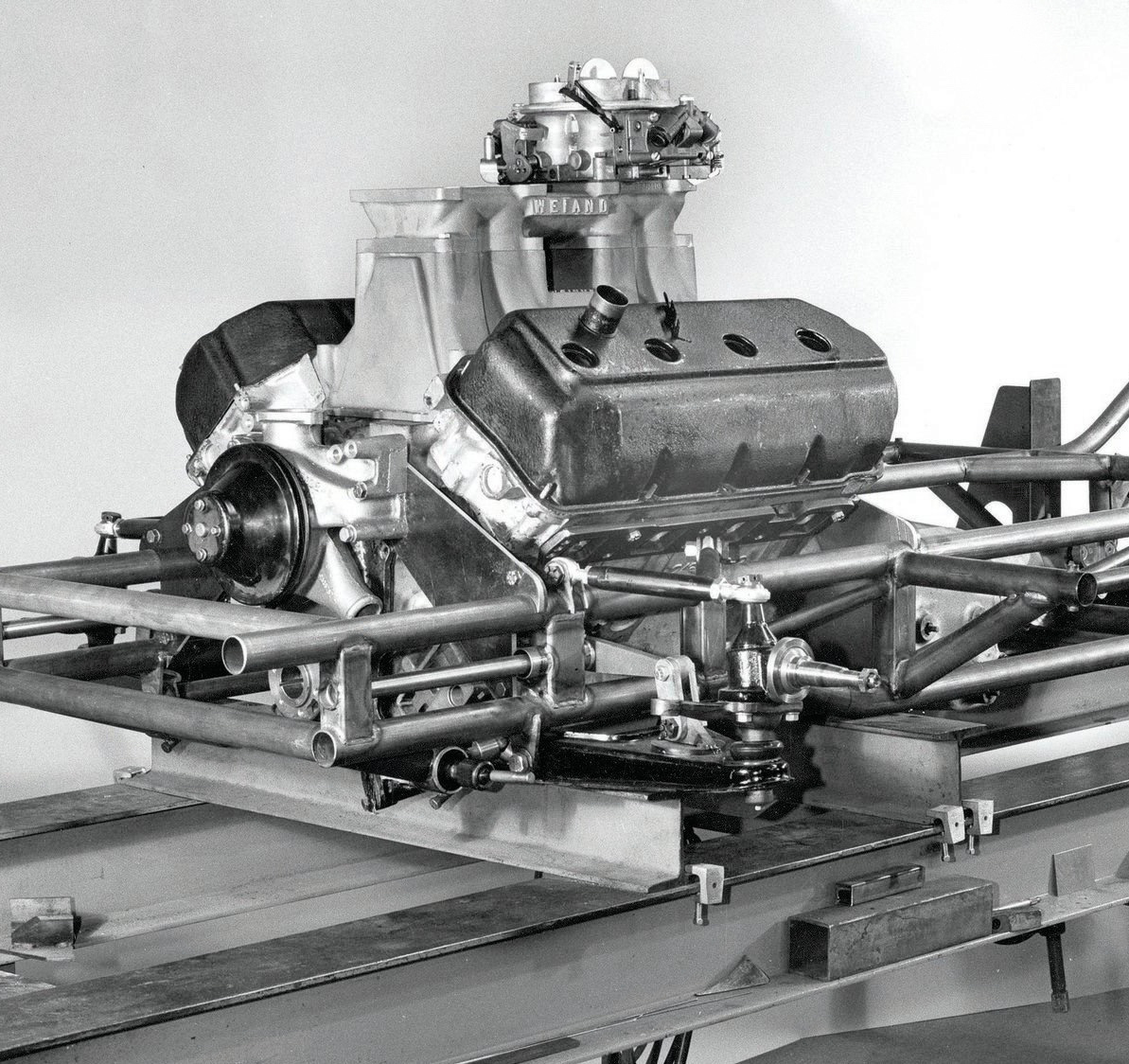

Designed for NASCAR stock car racing, the Circuit Racing version is revealed with the tell-tale A117 “bathtub” intake manifold designed by Chrysler engineers for the NASCAR teams that ran Dodge and Plymouth racecars on the track.

As seen in the photo shown above (with the Circuit Racing HEMI engine staged between the Dodge and Plymouth Hardtops), the large, round silver-hued air cleaner used in NASCAR racing is of rear-intake air design. There’s a large rectangular opening in the rear that corresponds with the plenum chamber at the base of the windshield, providing relatively cool fresh air into the engine.

JANUARY 1964 HEMI BULLETIN

The Engineering Staff released an informative report on the new 426 HEMI engine with this opening page introduction:

“Chrysler Corporation’s hemispherical-head, maximum-performance engines are scheduled for 1964 production on the same basis as earlier competition-type powerplants. They are offered exclusively for the serious competitor who wants to enter supervised racing events. Their highly tuned, racing camshafts preclude the smooth, even idle found in ordinary engines. Manifold heat is sacrificed for maximum power, and thus, warm-up is slow. Cold weather starting is not the same as would be expected of family-type passenger cars. These engines are not recommended for everyday driving.”

The PHR article talked mostly about the HEMI engine and drag racing, but in reality the real reason the factory decided to invest its resources in reviving a HEMI-head engine was in an effort to do well on the super speedways of NASCAR stock car racing battles. Dodge and Plymouths with wedge heads were not doing an adequate job of keeping pace with rival makes on the big tracks (Ford was the main dominant force at the time, with the Pontiacs being the fastest before that) and legend has it that it was Lynn Townsend himself, the president of Chrysler, that had requested that the company engineers come up with a way to win the Daytona 500.

Tom Hoover, Don Moore and Willem Weertman of the Engineering Staff were among the Chrysler employees that had remembered the A311 Indy program from years back and that gave them the inspiration to build a new, modern HEMI engine to respond to the request from the boss rather than trying to do something with a wedge-type head, which would have perhaps brought them up to the power levels of the rivals but not surpass them. The request from the top was to do something that would bring victory at the racetrack for Chrysler Corporation, and these employees knew that the HEMI cylinder head would do it. Right then and there, the goal was get a new engine for the company and go out and win the Daytona 500.

It was the manager named Bob Cahill that originally wrote the Product Planning Letter to the Engineering Dept. that got the ball rolling on the Chrysler 426 HEMI project, and then Jack Charipar presented the letter to the upper management and it was made official. Chrysler (through the Dodge and Plymouth divisions) was going to make a hemispherical-head engine again! And the situation was different this time around as the original HEMI from the ‘50s started out as a passenger car engine and it was later used for racing applications; now, the new HEMI engine designed in 1963 was a racing engine from the get-go.

When it came time to lay out the design of these new HEMI heads, they kept the same basic design as the earlier versions: valves inclined to the centerline of the cylinder, dual rocker shafts were used per bank (however, this time around, they were supported via five V-shaped malleable iron stands) and secured with five center bolts into the cylinder head. Four additional head studs were incorporated into the new design. Rocker arms are high strength forged steel, long and narrow and of cantilever construction with adjusting screws/jam nuts on the ends with pushrod sockets. Wide bushings are used on the rockers to prevent cocking and because the added mass of them is on the pivot axis area, it isn’t important to reciprocating inertia. The 426 HEMI cylinder heads (made of cast iron and with machined combustion chambers) ended up being approximately one inch longer than the old 392 units.

SLIGHT TILT

One of the key differences between the various 1950s HEMI engines and this new 426-cid model was that their was a decision made to tilt, rotate the head assemblies inward by some three degrees, and this revision allowed for the exhaust rockers to be slightly shorted in length, plus made the total engine width a bit narrower, as these engines needed to be able to run down the Dodge Main assembly line and have the Dodge and Plymouth intermediate B-body inner fenders clear the assembled HEMI engine as it is lowered down for mating the engine to the body itself.

Tom Hoover is considered by many as “the father of the 426 HEMI” and in a 1984 interview that took place with Robert Oskiera of MoPerformance Magazine, Hoover talked a little bit about this modification: “I think the key to it was we could see it would be difficult to drop the body over the engine. What made it so successful was that we tilted the chamber with respect to the cylinder head gasket plain a little bit. I would like to think it was my insight that allowed us to do that in the best way so we wouldn’t compromise the exhaust port too badly. We didn’t get the exhaust rocker arm too long and too heavy. We got the best shot in the intake ports. There was maybe a little luck involved, but also a little insight.”

Hoover acknowledged in the interview that Frank Bialk was the designer’s name and that he had a three-dimensional insight and was an excellent layout man in the drafting business. Bialk did the head and valve work and Forbes Bunting did the manifolding. The original 426 HEMI Chamber Cylinder Head blueprint has March 28, 1963 listed as the “date started” date and “date finished” listed as May 3,1963.

The intake valve diameter of the 426 HEMI engine was a colossal 2.25 inches, and exhaust valves came in at 1.94 inches. These sizes alone show just how tremendous the breathing capabilities are of the beast and coupled with free-flowing ports and that the valves themselves are now made with thinner stems to lessen the valvetrain inertia, it’s obvious this was a real race engine and not passenger car item of everyday occurrence.

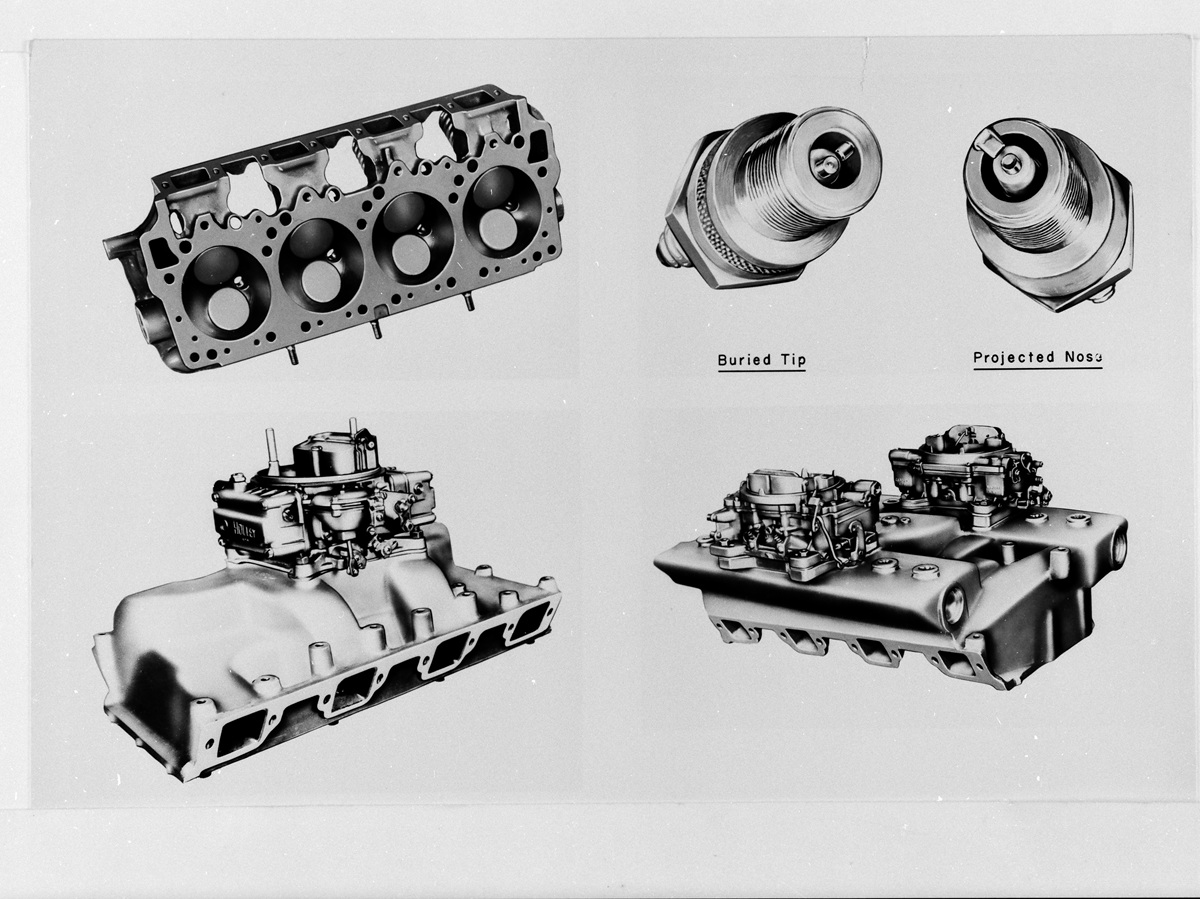

The cylinder block used for the 426 HEMI engine was based on the RB (raised deck) 426 wedge block as used on the Max Wedge engines of late 1962 / ’63 and it had a number of changes given to it in order to facilitate the addition of these new heads. Included in the changes were inner deck upgrades that allowed for the addition of four extra studs to bolt down the new HEMI heads, done by the adding of bosses in the tappet chamber of the block, providing five head bolts with the new design.

In addition, there were now provisions for oil drain-back holes from the rocker chamber back to the block (at the extreme outboard corners of the block that matches similar holes in the cylinder heads). The previous 426-wedge crankshaft was re-worked with shot-peened fillets on the journals and bearing surfaces hardened with a chemical-dip nitriding treatment that provides for improved fatigue resistance. The HEMI crank also includes a new eight-bolt flange design for added torque transfer strength. To keep everything intact during extended periods of high rpms, the main bearings were cross-bolted at the three center mains (#2, 3 and 4), adding lower cylinder block rigidity.

The engine itself is slightly lighter in weight as compared to the old 392 mill, thanks to thinner castings as more attention was given to weight savings because of advancements in modern casting methods. The new engine block gave some 32 cubic inches more capacity. Mechanical camshafts were used on these new engines and transistorized ignitions were not added to enhance extra spark with the dual-breaker point distributor. The manner of which the ignition wires now lead into the valve covers was via long high-resistance plastic connectors attached to the spark plug end of the ignition wires, then snapped on to the spark plug located at the bottom of the o-ring sealed spark plug tubes to each cylinder.

SPECIFIC APPLICATION MANIFOLDS

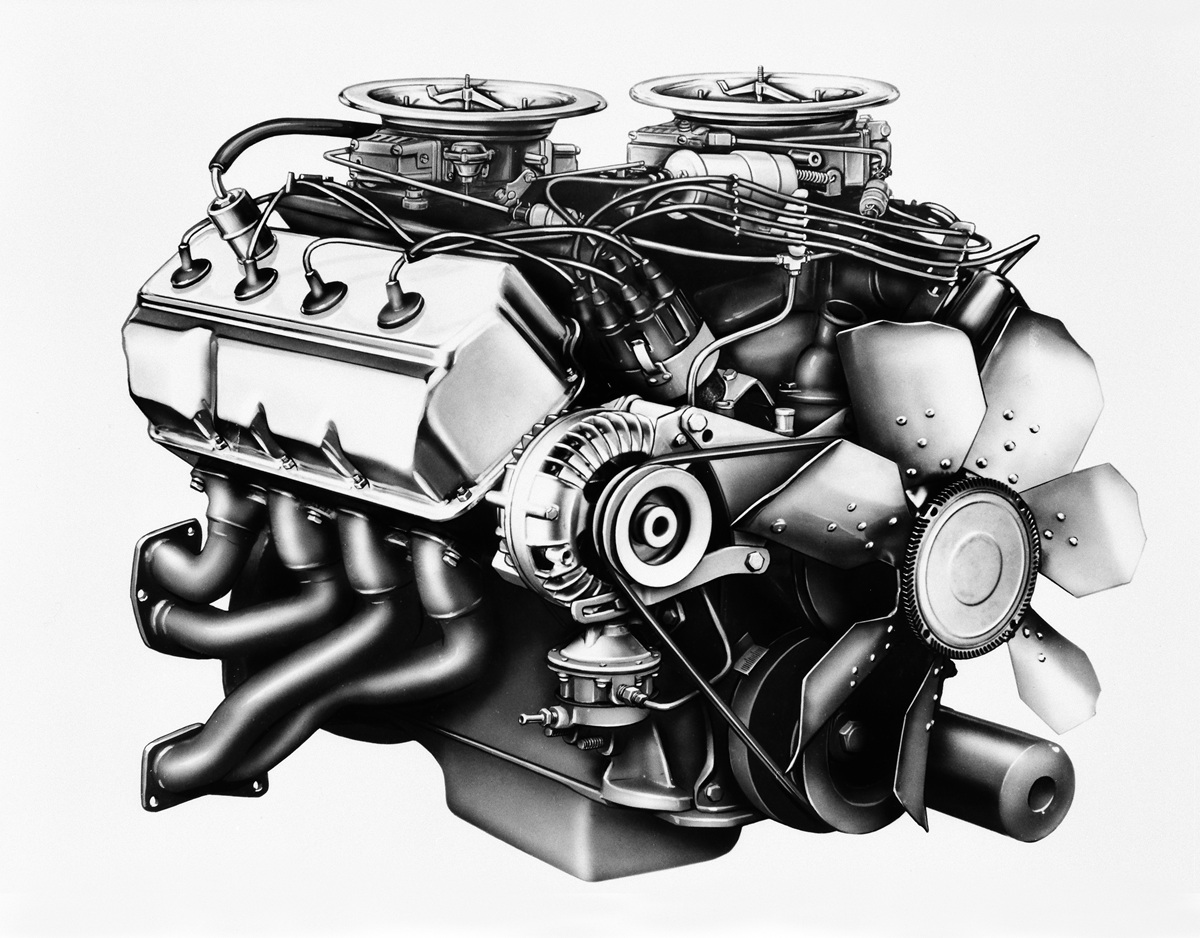

The new HEMI engine built to conquer NASCAR had 12.5:1 compression and came with a single 4-bbl. mounted atop a somewhat traditional two-level design (180-degree) intake manifold, and with large capacity internal runners for good airflow. With what had to be a totally tongue-in-cheek rating was when the factory said the circuit engine developed 400 horsepower, listed as taking place at 5600 rpm. Chrysler said this with a straight face and that figure was identical to their (now totally obsolete for NASCAR competition) race version of the 426-cid wedge, which came with one-and-a-half less points of compression and nowhere near the breathing capacity. Chrysler kept their real horsepower numbers private and only let the competition guess what these engines actually produced when they hit the racetracks! The two different intake manifolds shown were the single Holley 4bbl for stock car racing and the 2×4 cross ram (dual Carter model AFB-3816S 4bbl) for drag racing.

1964 A864 HEMI ACCELERATION ENGINES

The acceleration version of the 426 HEMI engine (A864) was available in two versions:

11.0:1 compression – 415 listed horsepower

12.5:1 compression – 425 listed horsepower

These drag race powerplants featured a ram-tuned “cross ram” aluminum intake with two Carter AFB carburetors, 1-11/16-inch primary and secondary bores, progressive throttle linkage. A single, oval-shaped air cleaner surrounds both four barrel carburetors. Cable-actuated manual chokes on both engines.

As with the Circuit Racing engine, specially designed tubular steel exhaust headers were included, made up of separate lengths of steel tubing welded to cast steel port flanges. Prestolite double breaker ignition used.

A990

For 1965, there were lightweight drag race package cars, B-body Dodge / Plymouth sedans fitted with the “A990” Race HEMI engines. We’ve covered a perfectly restored example back in April 2023.

A102 STREET HEMI

The whole idea for the new 1966 Street HEMI engine was to put this powerplant, albeit de-tuned, into the hands of customers that desired ultimate Mopar® street performance.

All Street HEMI engines (1966-1971) featured twin inline Carter four-barrels carburetors atop an aluminum intake manifold.

“Chrome Dome” air cleaner added to the impressive underhood visuals.

A/FX INJECTED

During the heyday of the A/FX era when Mopar racers like Sox & Martin, Dick Landy, the Ramchargers, etc., injected HEMI engines were all the rage! There were both 4-speed cars and those that ran automatics, and Chrysler’s performance engineers did extensive testing in both the laboratory and on the track to achieve optimum horsepower results. The inlet pipes, or “stacks”, were tuned to length as to what transmissions were run, automatics ran best with 23 inches in length, manuals ran best with 16.35 inches in length.

1968 SUPER STOCK RACE HEMI

For the 1968 NHRA Super Stock racing wars, Chrysler Corporation went all-out with lightweight Plymouth Barracuda and Dodge Dart package cars equipped with 426 Race HEMI engines. For in-depth reports, we previously covered both the Dodge and Plymouth versions here:

EARLY PRO STOCK

The early 1970s saw the introduction of the dual-plug HEMI heads, pioneered by Dick Landy, and the matching equipment included a tunnel ram intake (Weiand in this photo) and a pair of Holley 4500-series Dominators.

When Gary Dyer built a HEMI Dodge Colt for Mr. Norm’s Grand Spaulding Dodge, a match racer Pro Stock, he choose a 366cid de-stroked version to best fit the rules at the time.

FABRICATED TUNNEL RAM

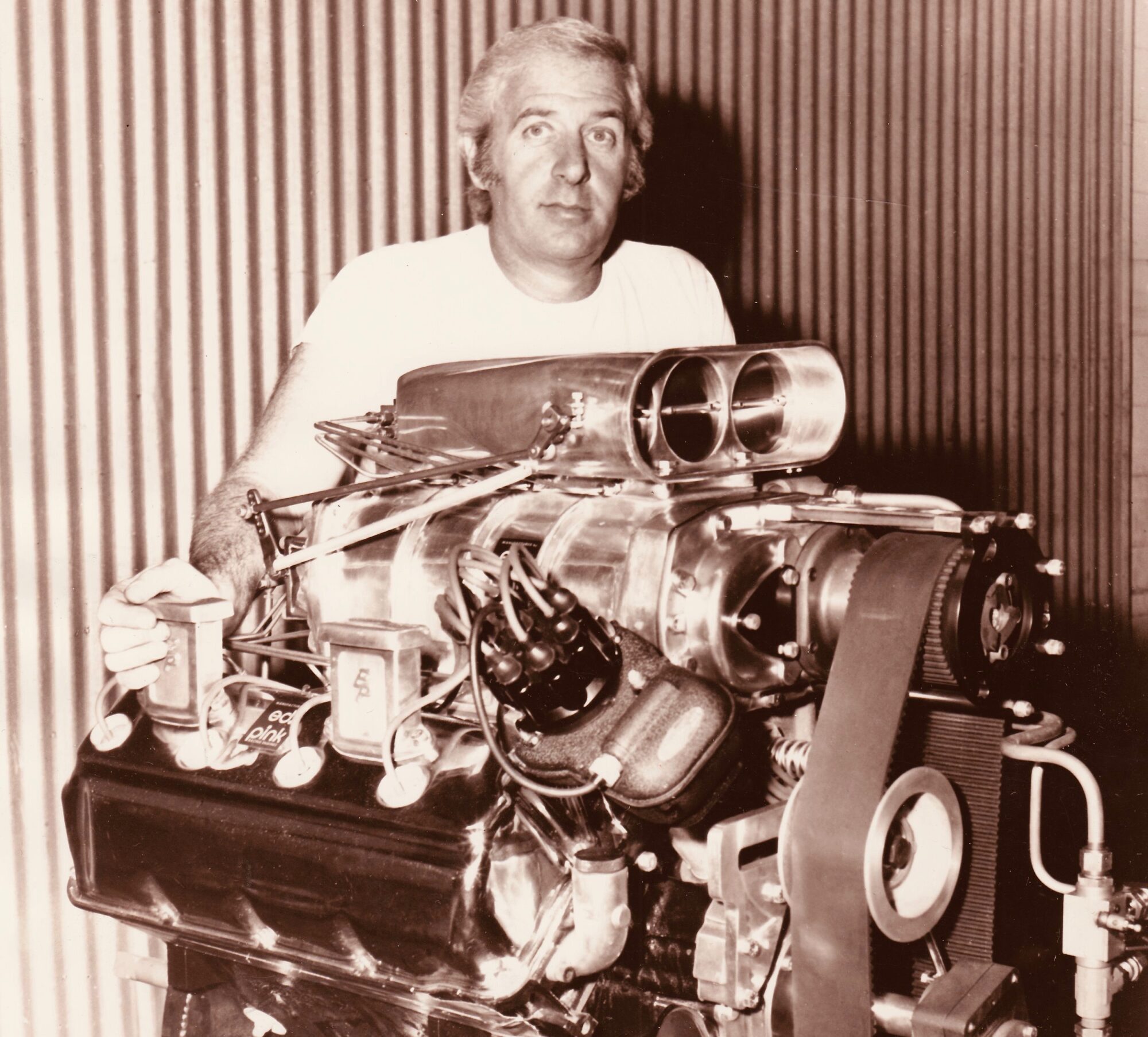

Seen here is an example of a Ray Barton race HEMI engine, a pair of Holley Dominator carburetors mounted on a custom aluminum sheet metal tunnel ram designed for optimum power for the RPM range of the particular engine.

DON GARLITS

When released, Chrysler sent a new 426 HEMI engine to Don Garlits and he built a new dragster for it, Swamp Rat VIII, specifically for fitting of the new HEMI. And like the 392, he ran 34 degrees of spark advance. Many years later, he told Hot Rod Magazine all about it:

“It was not producing the power of that the 392 was producing. It was mid-boggling,” said Garlits. “Then it all came to a head for me at Columbus. Saturday night match race, I ran three runs in the 8’s (using the 426 HEMI), and the 392 ran in the 7’s easy. And it (426) ran 191-192 mph, and the 392 was running 206-210 mph easy. I won the race, had top time, low ET, went to the tower to get paid. Sitting behind the desk was the track owner, desk completely clean on the top except the stack of money and a .45 pistol.”

Don said the situation was rather intimidating. Garlits, as he said, not at all happy that he was given $500 instead of the $750 that was owed to him. “So I went out of there, I told the crew what he just did to me.” Next, Garlits took it to the extreme with his reaction and was willing to just go out and blow it up, on purpose, return to the trusty 392 and potentially lose his Dodge sponsorship!

“I already figured out what I was going to do. I’m going to put 40-degrees spark into it! However, it actually was what the 426 wanted, more spark advance. First run, 214 mph! New world’s record! And it sounded good! Garlits then twisted the distributor even more, to 50 degrees in it. It ran 219 mph and change!

“That was it, that was the end of the 392 for me”, stated Garlits.

ED PINK

When racing engine builder Ed Pink assembled a 426 HEMI engine for supercharged nitromethane use, they were affectionally know as “Pink Elephants” and because of his last name, the drag racing publications and car magazines of the day really played up the “Black vs Pink” rivalry as often time on the nation’s drag strips, a car with a Keith Black HEMI would be lined up against an Ed Pink HEMI engine-powered car. There were other 426 race HEMI nitro engine builders in the era, such as Sid Waterman, Steve Montrelli and the Ramchargers. Pink’s last nitro customer was Harry Eberlin and the Super Shops car, circa 1981, as after that time frame, as he had explained, the individual Top Fuel and Funny Car crew chiefs had learned how to build and tune their own HEMI powerplants.

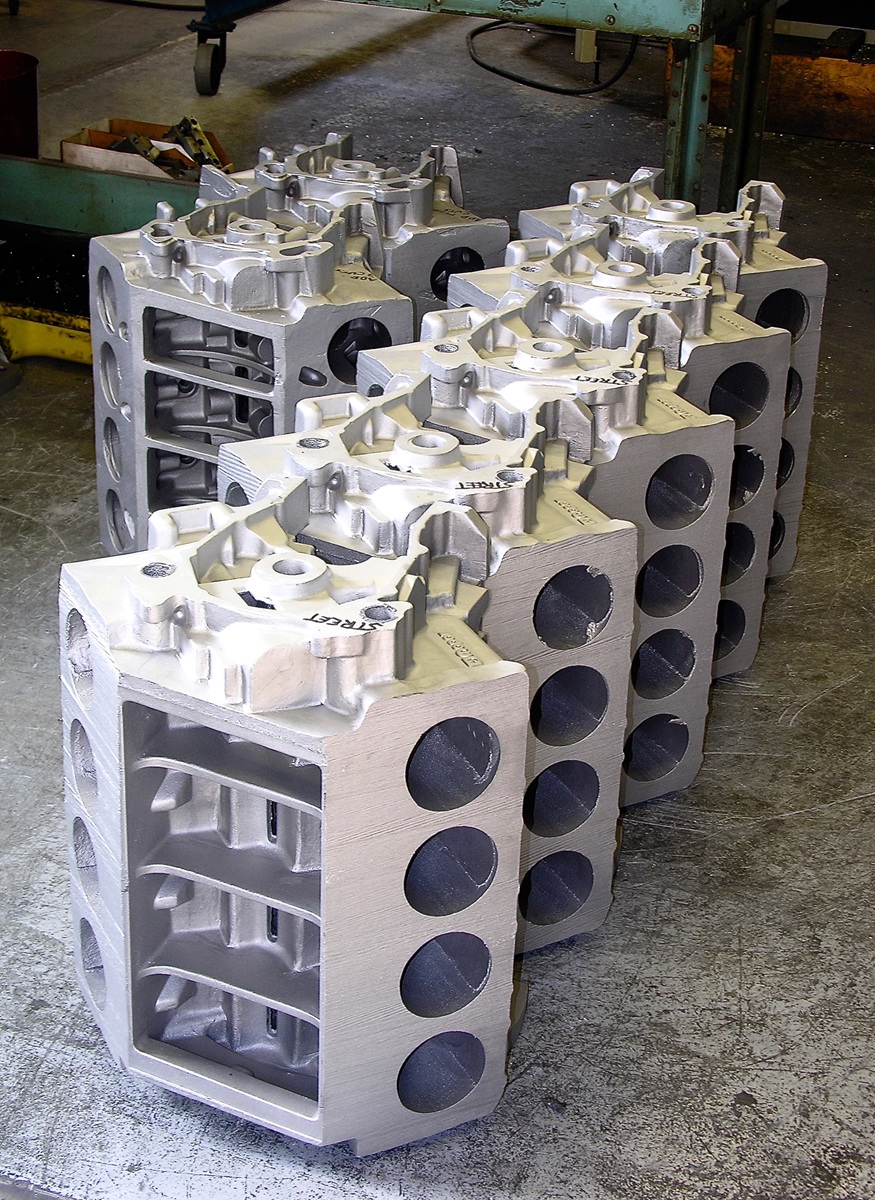

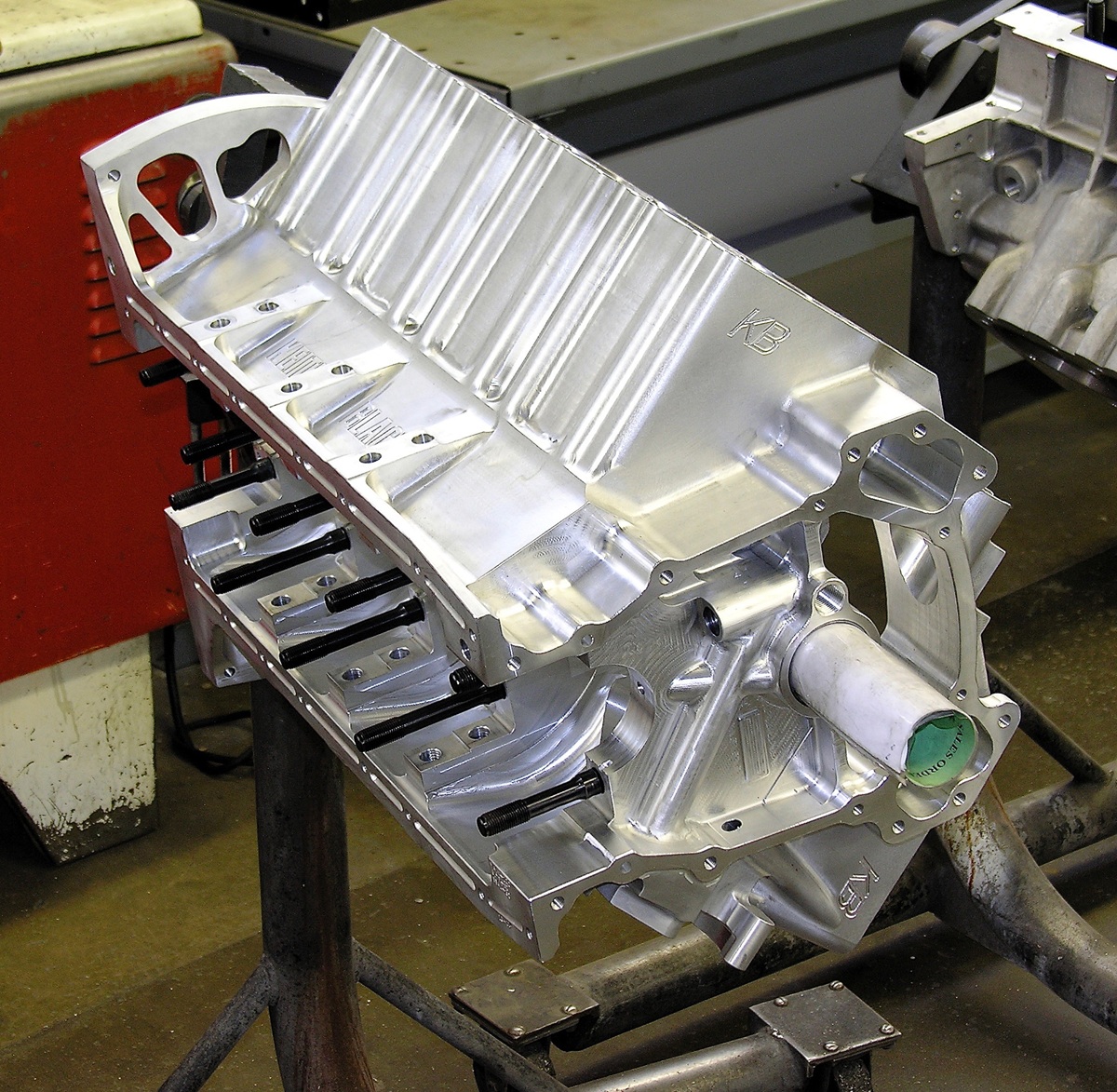

KEITH BLACK BLOCKS

The end of production of the 426 HEMI engine was a key event in the creation of the Keith Black aluminum 426 HEMI racing block, which came in 1974. The release of the famed KB engine block was without question the “shot heard around the world” for the sport of drag racing. With aluminum, racers gained several advantages: they saved 100 lb (45 kg) in weight, and had an engine that was now repairable. Keith wasn’t the first one to market a race block for dragsters, but his 426 version made the biggest impact and completely changed the face of professional nitro racing, and would come to dominate the market. While today’s nitro racing required forged blocks, KB cast blocks are still being used mostly for street rods and other applications that they are still suitable for.

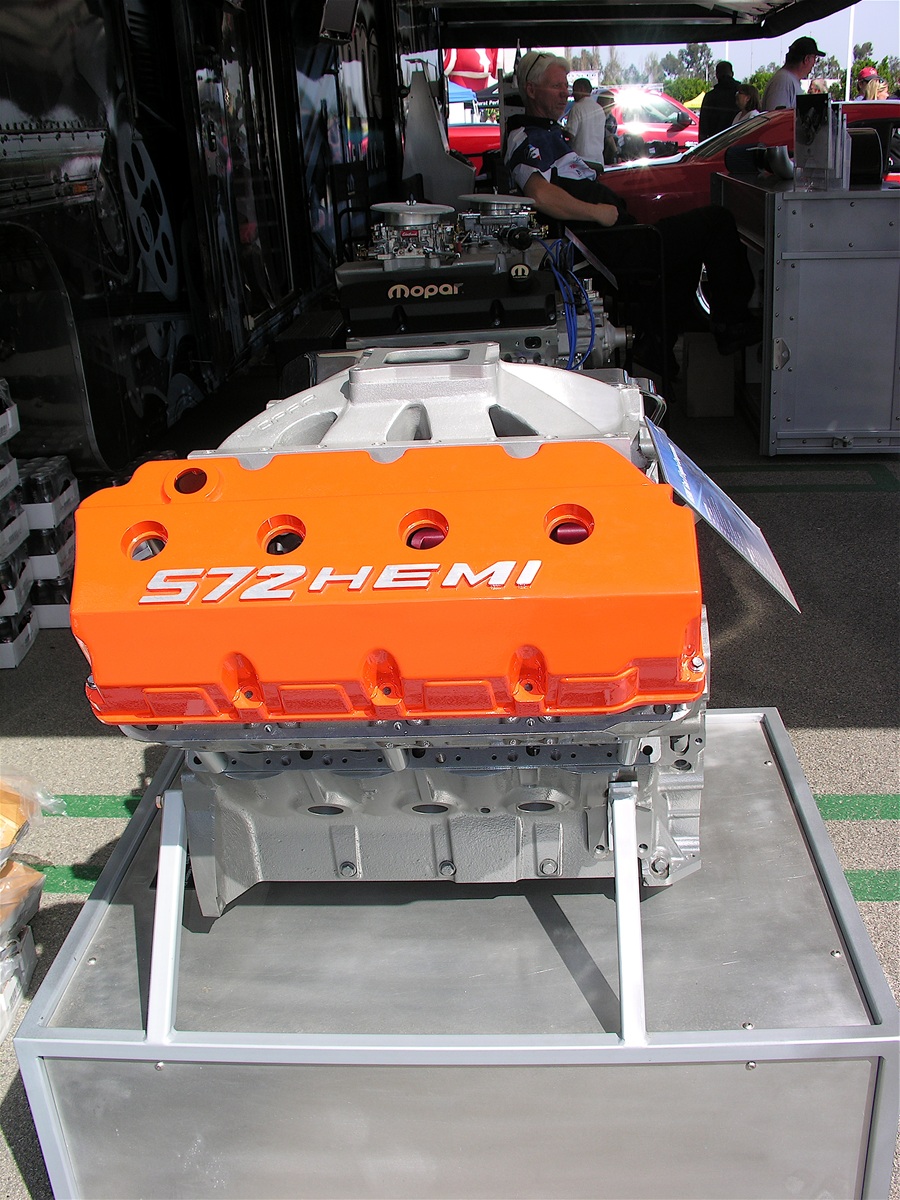

572

Retaining the stock camshaft location, the Mopar 572 HEMI engine was released some years back and geared especially for those that have a penchant for the maximum extreme! Retaining a 4.50-inch bore with 4.50-stroke, this combination has been a popular choice for those that want more horsepower and torque as compared to the smaller displacement versions, and considered offering the “most bang for the buck.”

CHROME HEADERS

Over the years, for 426 HEMI use in A- B- and E-body Mopar cars, there’s been the wide availability of tubular headers from numerous manufacturers, including: Hooker, Doug Thorley, Cyclone, Hedman, Jardine, JR and Stahl. And these days, as shown here, chromed 2 1/4-inch primary diameter headers are available from TTI Exhaust.

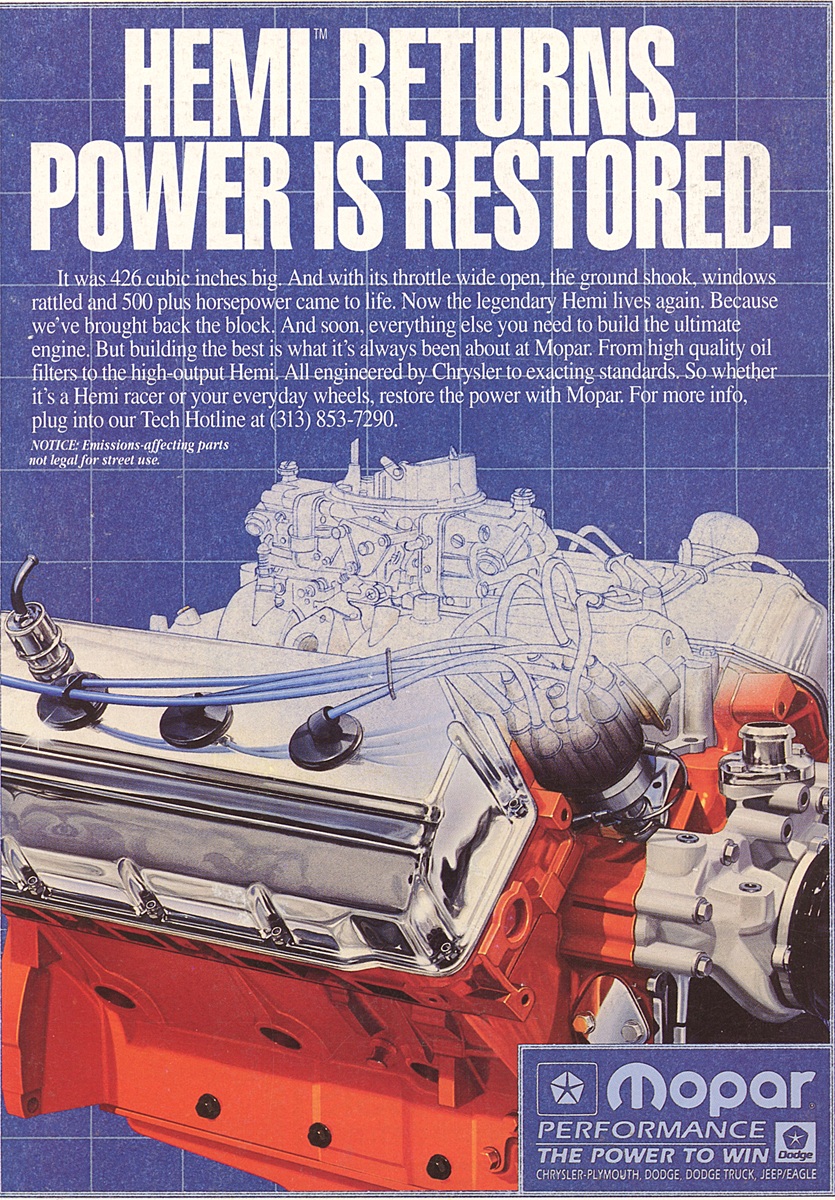

AUTHENTIC MOPAR HEMI BLOCKS / CRATE ENGINES

It was 1998 when Mopar Performance reintroduced the 426 HEMI block, all thanks going to Joe Higler, the reincarnation of an iconic Chrysler engine. Also helping the cause was that the factory had brought back crankshafts, connecting rods, rocker arms, iron and aluminum cylinder heads, chrome valve covers and intake manifolds. This “HEMI RETURNS. POWER IS RESTORED.” advertisement was a welcome announcement to worldwide HEMI lovers!

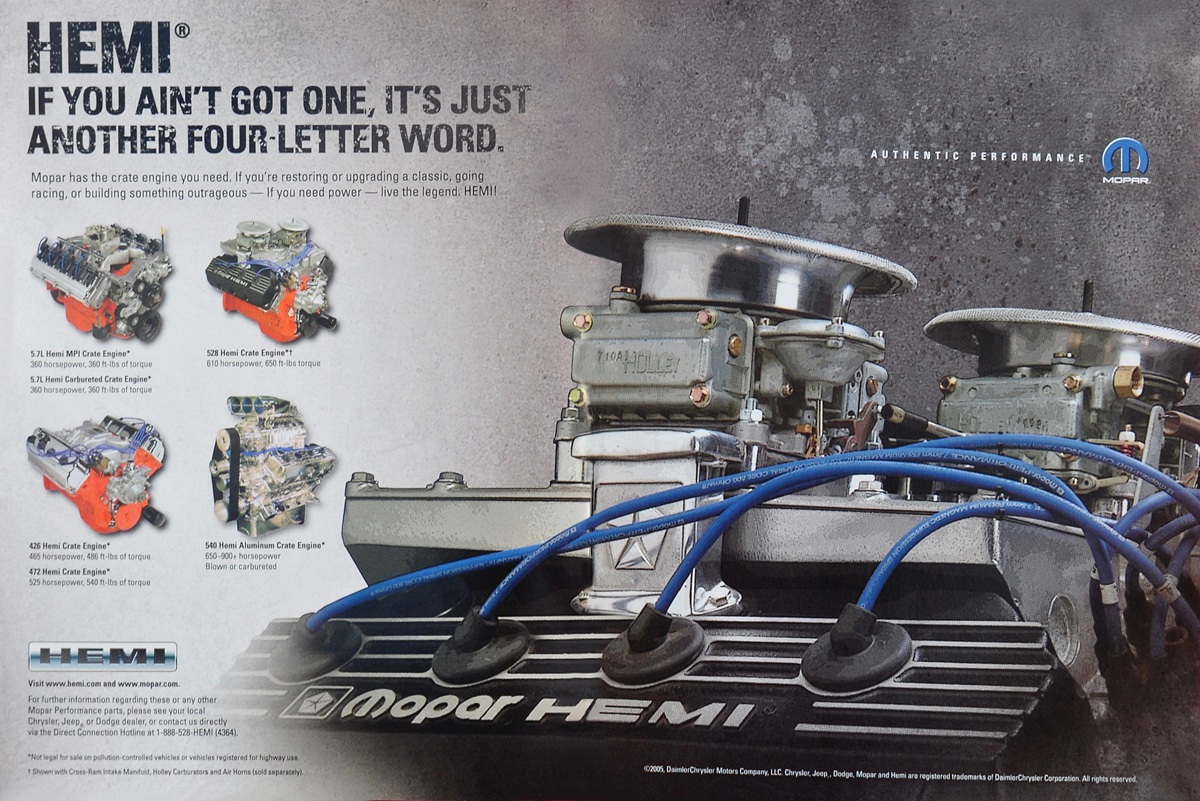

This 2005 DaimlerChrysler Motor Company LLC “Authentic Performance Mopar” ad highlights HEMI Crate Engines in 426, 472 and 528 cubic inch displacement sizes. In addition, there was the 540-cid Aluminum Crate Engine, which was sourced by Keith Black Racing Engines.

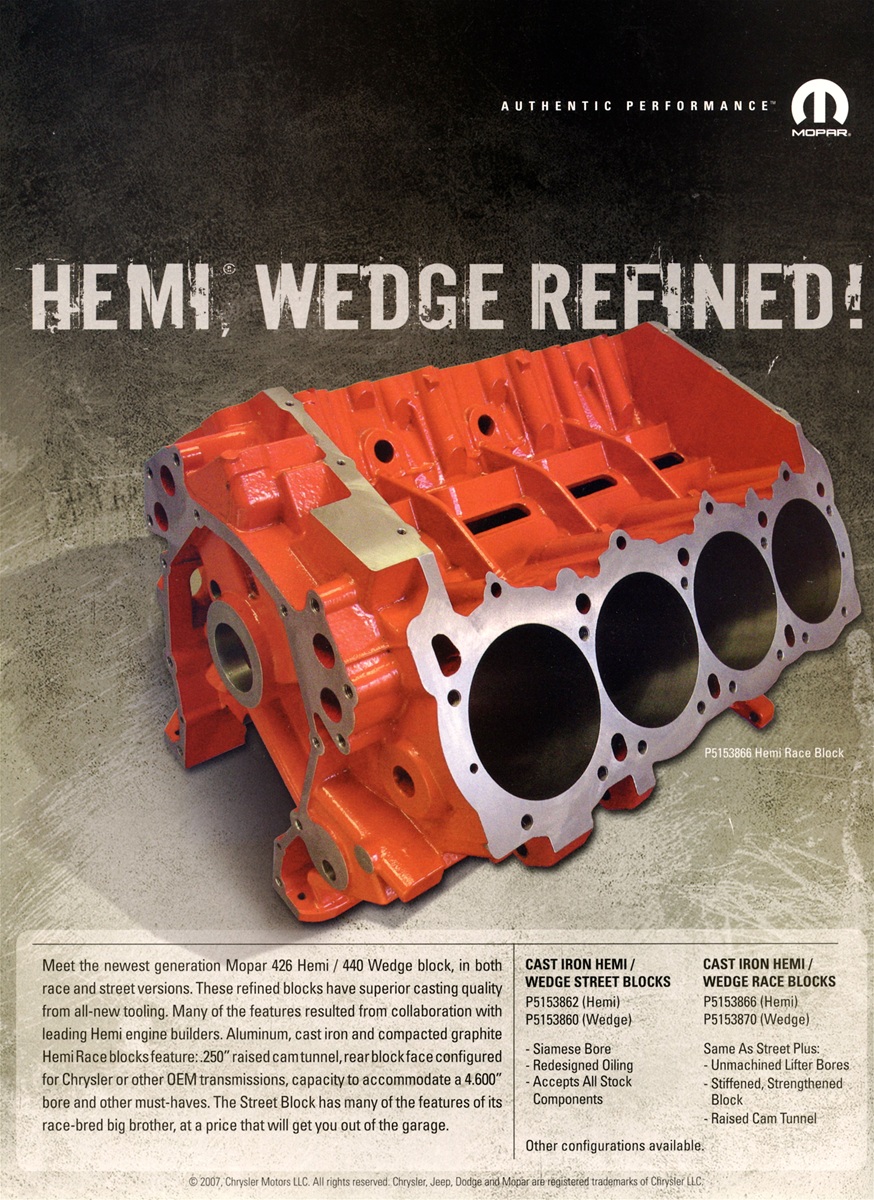

2007 Chrysler Motors LLC ad announcing the new HEMI, WEDGE engine block, available in “Street” and “Race” configurations. All-new tooling was used and the design features came as a result of collaboration with the top HEMI engine builders of that time frame.

TIME TABLE FOR EARLY DEVELOPMENT

DECEMBER 1962

A request was made of Engineering Staff to develop an engine and vehicle combination capable of winning stock car competitive closed circuit course track events throughout the country.

JANUARY 1963

The design of the new HEMI engine began in January 1963 with the February 1964 Daytona Beach, FL, NASCAR race set as the first target date.

JULY 1963

Experimental procurement of the 426-cubic-inch HEMI engine was started, and completed by the end of November.

DECEMBER 1963

It was on December 6th that the first engine ran under its own power.

FEBRUARY 1964

On February 23rd, HEMI cars took 1st – 3rd (Richard Petty, Jimmy Pardue, Paul Goldsmith) and fifth (Jim Pascal) at the Daytona 500. Petty led 184 of the 200 laps of the race, which sent shock waves through the garage areas of the competition! An amazing success, and in a major league rushed timeframe.

RICHARD PETTY ON WINNING

Here’s how race winner Richard Petty summarized the impact of the new HEMI engine at the race in his 1971 autobiography: “We got our HEMI ready for Daytona, and when we got it to the track, even I couldn’t believe how strong it was. We immediately began turning in record times, and everybody stopped what they were doing to take notice – particularly the Ford people. I qualified at an unbelievable 174.418 mph. Then Paul Goldsmith went out in another Plymouth and sat on the pole with an average speed of 174.910 mph! We had waited a long time for this. The fastest Ford had qualified at was only 169. The 1964 Daytona was a dream. I got out front early and stayed there most of the time. The only car that could run with us was Goldsmith’s, and I managed to keep him behind me to the checkered flag. Man, did that HEMI perform!”

Check out this Tom Hoover “lost video” where it’s all explained.

Author: James Maxwell

0 Comments